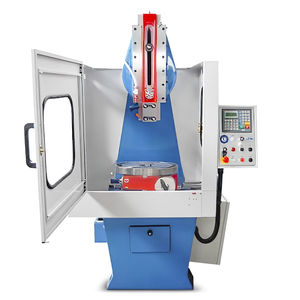

NC slotting machine 300M 1AC2-axis

Add to favorites

Compare this product

Characteristics

- Control type

- NC

- Number of axes

- 2-axis

Description

Pre-programmed and reversible longitudinal slot machining and tool lift obtained by alternating table movement. Once the pre-programmed slot depth has been reached, in automatic the machine performs a number of finishing strokes and the ram stops in its top position and the workpiece table in automatic returns to machining start cycle position. Workpiece table with central through hole. 20° tilting head (in both directions). Inverter controlled variable stepless slotting speed with potentiometer incorporated in the control panel. The machine incorporates an electro-pump for the tool cooling system and vacuum pump operated ram and trolley lubrication system. Maintenance tools and machine instruction manual are provided.

Machine designed and manufactured to EC standards and directives.

Catalogs

No catalogs are available for this product.

See all of CAMS srl‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.