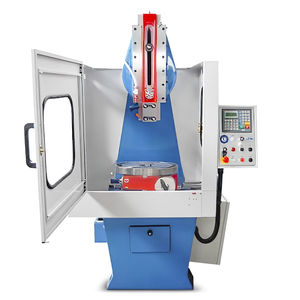

NC slotting machine 850 4AC 4-axisrotating table

Add to favorites

Compare this product

Characteristics

- Control type

- NC

- Number of axes

- 4-axis

- Options

- rotating table

Description

Our Slotting Machine 4AC is the result of 30 years experience and research in design and development of industrial slotting machinery and equipment.

The CAMS slotting machine offers a number of important features :

robust construction: the main structure is manufactured in robust thickness sheet metal (heat treated and processed);

tables in high quality grade cast-iron (grade G30);

the turntable with a working diameter of 1000mm and central 350mm diameter central through hole;

travel surfaces in cast-iron and PTFE with lubrication system designed to substantially reduce the stick/slip effect axes move on recirculating ball screw assemblies;

CAMS has recently improved the head by incorporating in-house designed and developed technological innovations. The ram has been modified in size to offer greater robustness and is driven by a brushless motor transforming it into a machining axis. Gears in an enclosed oil bath connect the drive system to the motor.

Travel surfaces on the head are in cast-in and PTFE ground and scraped.

Machine electrics have been modified offering greater machining performance and flexibility as well as incorporating improved technology:

automatic longitudinal and horizontal pre-programmed and reversible slot machining and automatic rotation of turntable for any required slot depth and diameter.

tool lift obtained by alternating table movements;

once the pre-programmed slot depth has been reached, in automatic the machine performs a number of pre-programmed finishing strokes and the ram stops in position Z- and the workpiece table in automatic returns to machining start cycle position.

Catalogs

No catalogs are available for this product.

See all of CAMS srl‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.