- Detection - Measurement

- Position, Speed and Acceleration Measurements

- Canberra Industries

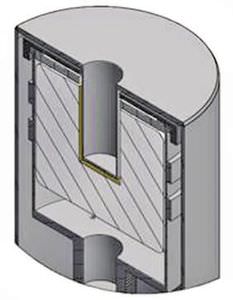

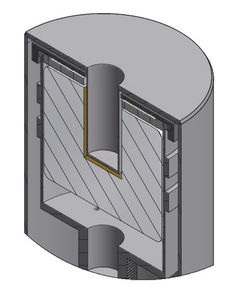

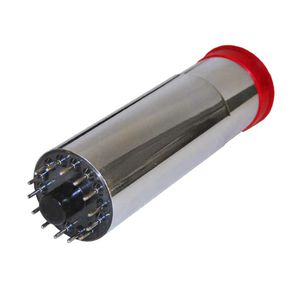

Detector REGe

Add to favorites

Compare this product

Description

The reverse-electrode (REGe) detector is similar in geometry to other coaxial germanium detectors with one important difference.

• Spectroscopy from 3 keV to >10 MeV

• Ultra-thin ion implanted contacts

• Radiation damage resistant

• Excellent timing resolution

• High energy rate capability

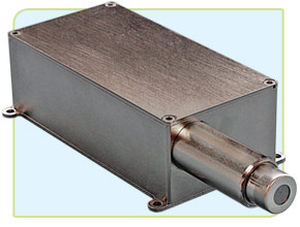

• Equipped with Intelligent Preamplifier

• Diode FET protection

• Warm-up / HV shutdown

• USB 2.0 Serial Interface

The reverse-electrode (REGe) detector is similar in geometry to other coaxial germanium detectors with one important difference. The electrodes of the REGe detector are opposite from the conventional coaxial detector in that the p-type electrode, (ion-implanted boron) is on the outside, and the n-type contact (diffused lithium) is on the inside. There are two advantages to this electrode arrangement – window thickness and radiation damage resistance.

The ion-implanted outside contact is extremely thin (0.3 μm) compared to a lithium-diffused contact, enabling the REGe detector to cover a broad energy range from 3 keV up to several MeV. REGe detectors are normally equipped with a carbon composite window which is robust and provides excellent transmission to below 10 keV. Beryllium or aluminum windows are also available. Aluminum is preferred when there is no interest in energies below 20 keV and improved ruggedness is desired. Beryllium should be selected to take full advantage of the low energy capability (down to 3 keV) of the REGe detector.

It has been found that radiation damage, principally due to neutrons or charged particles, causes hole trapping in germanium.

Catalogs

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.