- Metrology - Laboratory

- Laboratory Equipment

- Chamber oven

- Carbolite Gero

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

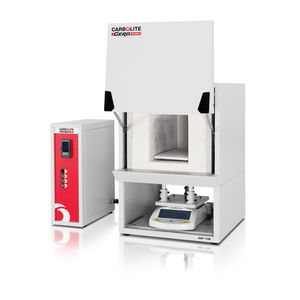

Chamber furnace AAF 11 seriespreheatingcalcinationcombustion

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber

- Function

- preheating, calcination

- Heat source

- combustion

- Other characteristics

- continuous, digital, laboratory

- Maximum temperature

1,100 °C

(2,012 °F)- Capacity

3 l, 7 l

(0.79 gal, 1.85 gal)- Width

375 mm, 430 mm

(14.76 in, 16.93 in)- Height

585 mm, 650 mm

(23.03 in, 25.59 in)- Depth

485 mm, 740 mm

(19.09 in, 29.13 in)

Description

The AAF ashing furnace range is designed specifically to provide optimum ashing conditions to ensure complete combustion of the sample.

The AAF 11/3 & AAF 11/7 ashing furnaces provide a continuous flow of preheated air through the chamber, and are designed to comply with ISO 1171:2010, ASTM D3174-04: 2010 and ASTM D4422.

Standard features

Carbolite Gero 301 controller, with single ramp to set-point & process timer

Large floor area allows for large numbers of samples

Ideal for ashing foods, plastics, coal & other hydrocarbon materials

Designed to comply with ISO 1171:2010, ASTM D3174-04:2010 and ASTM D4422

Wire elements are protected from chemical & mechanical damage by a hard wearing alumina based liner

4 sided heating (2 sides, roof & hearth)

Air inlet & tall chimney give airflow of 4 to 5 changes per minute

Low chamber height holds airflow close to samples for optimum combustion

Powerful elements with graded winding compensate for heat loss due to high airflow

Preheating of air before it enters the chamber gives excellent uniformity

Sample tray and loading handle

Options (specify these at time of order)

2 phase electrical supply for AAF 11/7

Over-temperature protection (recommended to protect valuable contents & for unattended operation)

A range of sophisticated digital controllers, multi-segment programmers and data loggers is available. These can be fitted with RS232, RS485 or Ethernet communications

Catalogs

Related Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Drying furnace

- Laboratory furnace

- Combustion furnace

- Gas furnace

- Baking oven

- Industrial furnace

- High-temperature furnace

- Controlled atmosphere furnace

- Automatic furnace

- Vacuum furnace

- Digital furnace

- Continuous furnace

- Annealing furnace

- Forced convection furnace

- Programmable furnace

- Air circulating furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.