- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

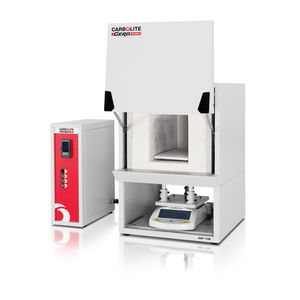

Chamber furnace SBCF seriesheat treatmentsinteringelectric

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber

- Function

- heat treatment, sintering

- Heat source

- electric

- Other characteristics

- programmable, industrial

- Maximum temperature

1,100 °C

(2,012 °F)- Capacity

512 l, 1,728 l, 3,375 l

(135.26 gal, 456.49 gal, 891.58 gal)- Width

1,710 mm, 2,110 mm, 2,410 mm

(67.32 in, 83.07 in, 94.88 in)- Height

Max.: 3,053 mm

(120.2 in)Min.: 2,130 mm

(83.86 in)- Depth

1,354 mm, 1,754 mm, 2,054 mm

(53.31 in, 69.06 in, 80.87 in)

Description

The robust construction of the SBCF large chamber furnace makes it ideal for applications such as the heat treatment of steels and alloys, ceramics sintering and aerospace heat treatment.

The SBCF chamber furnace is an industrial scale furnace based on a modular design principle which can be adapted to various applications. The furnace chamber is cubic in shape and is available in three sizes.

The furnace has a side hinged door and a fixed hearth. As an option the hearth can fitted to a bogie so it can be pulled out of the furnace on a track system. This hearth design technique also allows the furnace to be easily adapted to a vertical lift arrangement to provide an elevator hearth, in which case the door would become a fixed side of the chamber.

Under hearth heating and free radiating coiled wire elements on four sides. This design provides the option of single and 3-zone temperature control and for applications demanding the best uniformity possible, such as AMS 2750F (this can be combined with an optional air circulation fan).

The construction uses low thermal mass insulation materials to maximise running efficiency whilst using robust refractory materials where physical strength is required such as the loading area of the hearth. Silicon carbide (SiC) tiles are fitted on the hearth to provide a hard wearing surface.

STANDARD FEATURES

3-zone control fitted with 1 x programmable EPC3008P1 and 2 x EPC3016 slaves with retransmission of setpoint

Over-temperature protection

Furnace can meet the requirements of AMS2750F

Under hearth heating and free radiating coiled wire elements on four sides

Excellent temperature uniformity and control

Catalogs

Related Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Drying furnace

- Laboratory furnace

- Combustion furnace

- Gas furnace

- Stainless steel furnace

- Baking oven

- Industrial furnace

- Controlled atmosphere furnace

- High-temperature furnace

- Automatic furnace

- Vacuum furnace

- Digital furnace

- Annealing furnace

- Continuous furnace

- Forced convection furnace

- Programmable furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.