- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

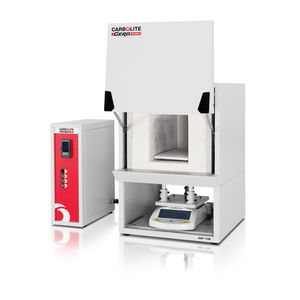

Rotary retort furnace GLO seriesheat treatmentannealinggas

Add to favorites

Compare this product

Characteristics

- Configuration

- rotary retort

- Function

- heat treatment, annealing

- Heat source

- gas

- Atmosphere

- vacuum, controlled atmosphere

- Maximum temperature

600 °C, 900 °C, 1,100 °C

(1,112 °F, 1,652 °F, 2,012 °F)- Capacity

10 l, 40 l, 75 l, 120 l, 260 l

(2.64 gal, 10.57 gal, 19.81 gal, 31.7 gal, 68.68 gal)- Width

Max.: 2,400 mm

(94.49 in)Min.: 850 mm

(33.46 in)- Height

Max.: 2,600 mm

(102.36 in)Min.: 1,800 mm

(70.87 in)- Depth

Max.: 4,000 mm

(157.48 in)Min.: 1,600 mm

(62.99 in)

Description

The GLO annealing furnace features a vacuum tight retort with highly symmetric positioning of the heating elements. The heating elements are CrFeAl, also known as APM, and are embedded in the ceramic fibre insulation.

The GLO is often equipped with a vacuum pumping system to reduce the Oxygen levels prior to heat treatment. To ensure the lowest possible contamination levels, several cycles of vacuum and Nitrogen purging occur to create a pure atmosphere in the retort. Vacuum assisted cycling is far superior compared to simply flowing Nitrogen through the retort as the process creates a pure atmosphere faster and requires less Nitrogen. After Oxygen levels have been reduced, heat treatment begins under an inert atmosphere with a slight overpressure.

The highest possible temperature of the GLO annealing furnace is 1100°C for heat treatment with an atmosphere. The front door of the cylindrical retort can be heated if required. At the water cooled front door, the gas is purged inside the GLO. It is preheated by the radiation shields, which are inserted at the front. The GLO is provided with a rear port for the expulsion of any gaseous by-products generated during the process.

The GLO can be operated manually or with the use of an automated system. The furnace is available in sizes of 10 (mobile version), 40, 75, 120 and 260 litres. The retort is manufactured with temperature resistant steel alloy (1.4841). Other materials are available on request.

The annealing furnace may be operated with reactive gases such as Hydrogen, which requires appropriate safety technology.

Catalogs

Related Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Drying furnace

- Laboratory furnace

- Combustion furnace

- Gas furnace

- Stainless steel furnace

- Baking oven

- Industrial furnace

- Controlled atmosphere furnace

- High-temperature furnace

- Automatic furnace

- Vacuum furnace

- Digital furnace

- Continuous furnace

- Annealing furnace

- Forced convection furnace

- Programmable furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.