- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

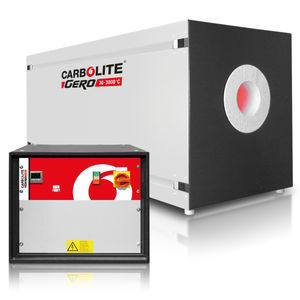

Tubular furnace FST seriesannealingsinteringquenching

Add to favorites

Compare this product

Characteristics

- Configuration

- tubular

- Function

- annealing, sintering, quenching, tempering, aging, drying, calcination, brazing

- Heat source

- electric

- Atmosphere

- vacuum

- Other characteristics

- horizontal

- Maximum temperature

1,300 °C

(2,372 °F)- Width

460 mm, 680 mm, 1,200 mm, 1,700 mm, 4,700 mm

(18.11 in, 26.77 in, 47.24 in, 66.93 in, 185.04 in)- Height

530 mm, 590 mm, 690 mm, 2,200 mm

(20.87 in, 23.23 in, 27.17 in, 86.61 in)- Depth

560 mm, 620 mm, 1,100 mm, 1,200 mm

(22.05 in, 24.41 in, 43.31 in, 47.24 in)

Description

The FST, single zone, and FZS, 3-zone, split tube furnaces can be used either vertically or horizontally and have a maximum operating temperature of 1300 °C.

The split heating module allows either easy positioning of the work tube or positioning around reactors which have fixed end flanges. The split design may also allow faster cooling of the sample. Cooling channels are engineered into the housing to aid with convection cooling of the outer case. A handle is attached to the upper half of the split tube furnace with two quick-release clamps to safely unlock and lock the furnace.

The two furnace halves are ceramic fibre modules with high quality APM wire heating elements mounted in the insulation, held in position by a ceramic holding ridge. A safety switch protects the operator by switching off the heating elements once the furnace is opened.

Customized versions and a comprehensive range of tube furnace accessories complete the available options.

Application Examples

ageing, annealing, brazing, calcination, catalyst research, CIM, coating, CVD, degassing, drying, hardening, MIM, miniplants, pyrolysis, sintering, soldering, sublimation, synthesis, tempering, test fuel cells, thermocouple calibration

Standard features

Carbolite Gero 3216CC controller, with single ramp to setpoint & process timer

3-zone models fitted with 1 x 3216CC and 2 x 3216CC end zone controllers, with retransmission of setpoint

Accepts work tubes with outer diameter up to 150 mm

Single-zone heated lengths of 200, 500 or 1000 mm

3-zone heated lengths of 500 or 1000 mm

Split design allows work tubes or reactors with fixed flanges to be accommodate

Related Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Drying furnace

- Laboratory furnace

- Combustion furnace

- Gas furnace

- Stainless steel furnace

- Baking oven

- Industrial furnace

- High-temperature furnace

- Controlled atmosphere furnace

- Automatic furnace

- Vacuum furnace

- Digital furnace

- Continuous furnace

- Annealing furnace

- Forced convection furnace

- Programmable furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.