- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

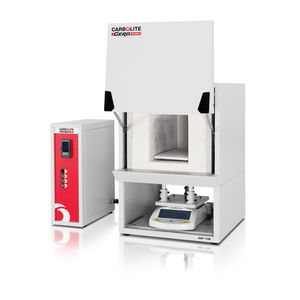

Chamber furnace LCF seriesheat treatmentannealingsintering

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber

- Function

- heat treatment, annealing, sintering, quenching, tempering

- Heat source

- electric

- Other characteristics

- programmable, custom, digital, industrial

- Maximum temperature

1,200 °C, 1,400 °C

(2,192 °F, 2,552 °F)- Capacity

Max.: 725 l

(191.52 gal)Min.: 125 l

(33.02 gal)- Width

Max.: 1,480 mm

(58.27 in)Min.: 1,180 mm

(46.46 in)- Height

Max.: 2,620 mm

(103.15 in)Min.: 2,310 mm

(90.94 in)- Depth

Max.: 2,470 mm

(97.24 in)Min.: 1,590 mm

(62.6 in)

Description

The robust construction of LCF industrial chamber furnaces makes them ideal for applications such as the heat treatment of steels and alloy, ceramics sintering and aerospace heat treatment.

The LCF industrial furnace range is often customised in order to precisely meet the user’s requirements. This range also provides a foundation upon which a wide range of custom modifications can be added. Typical examples of which are the more sophisticated control systems and data recording that is required for applications such as AMS 2750E heat treatment under Nadcap. Solutions are available to handle heavier loads or assist in loading and unloading the furnace, or larger chamber sizes than are offered in the standard range.

Standard features

Programmable 3216P1 controller

Over-temperature protection

Excellent uniformity and control

Robust construction using hollow steel section & zinc coated steel sheet

Double skin construction ensures safe outer case temperature

Manually operated vertically opening door keeps the hot face away from the operator

Low thermal mass insulation for high energy efficiency

Hard wearing silicon carbide tiled hearth

1200°C range heated by heavy gauge wire elements in roof and below the hearth

1400°C range heated by high quality silicon carbide elements in roof and below the hearth

Safety door interlock isolates power from the elements whenever the door is opened

Options (specify these at time of order)

A range of sophisticated digital controllers, multi-segment programmers and data loggers is available.

Catalogs

Related Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Drying furnace

- Laboratory furnace

- Combustion furnace

- Gas furnace

- Stainless steel furnace

- Baking oven

- Industrial furnace

- High-temperature furnace

- Controlled atmosphere furnace

- Automatic furnace

- Vacuum furnace

- Digital furnace

- Continuous furnace

- Annealing furnace

- Forced convection furnace

- Programmable furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.