- Metrology - Laboratory

- Laboratory Equipment

- Bell oven

- Carbolite Gero

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

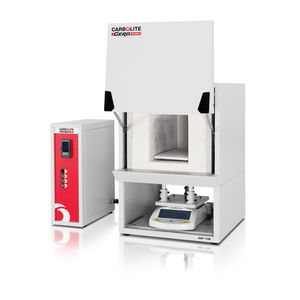

Bell furnace BLF serieselectriclaboratory

Add to favorites

Compare this product

Characteristics

- Configuration

- bell

- Heat source

- electric

- Other characteristics

- laboratory

- Maximum temperature

1,600 °C, 1,700 °C, 1,800 °C

(2,912 °F, 3,092 °F, 3,272 °F)- Capacity

3 l, 8 l, 21 l

(0.79 gal, 2.11 gal, 5.55 gal)- Width

Min.: 750 mm

(29.53 in)Max.: 1,250 mm

(49.21 in)- Height

Min.: 1,025 mm

(40.35 in)Max.: 1,850 mm

(72.83 in)- Depth

Min.: 530 mm

(20.87 in)Max.: 900 mm

(35.43 in)

Description

BLF bottom loading furnaces use an electrically operated elevator hearth, which as it rises into the furnace chamber, lifts the load into the heated zone.

This furnace provides the following advantages: easy loading of samples and uniform heating achieved by locating elements in all six side walls of the chamber.

The 1600 °C is ideal for sintering of zirconia dental crowns and frameworks. The silicon carbide heating elements will not cause discolouration of the zirconia.

Standard features

Programmable 3216P1 controller

Ideal for: sintering high performance ceramics, melting glass under high temperature or working with modified atmospheres

Rapid heating & cooling cycles can be achieved through raising & lowering the hearth

Electrically operated elevator hearth protects operator from the chamber's radiant heat

Hearth cage with safety interlock

Excellent temperature uniformity as a result of the hexagonal chamber

Overtemperature protection to protect load or furnace during unattended operation

Options (specify these at time of order)

A range of sophisticated digital controllers, multi-segment programmers and data loggers is available. These can be fitted with RS232, RS485 or Ethernet communications

Compatible crucibles

Modified hearth for the introduction of gases into an inverted crucible (not gas tight)

Radiation shutter

Customised options including: adaptation to introduce thermocouple or stirrer through the chamber roof and rotating hearth

VIDEO

Catalogs

Related Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Drying furnace

- Laboratory furnace

- Combustion furnace

- Gas furnace

- Baking oven

- Industrial furnace

- High-temperature furnace

- Controlled atmosphere furnace

- Automatic furnace

- Vacuum furnace

- Digital furnace

- Continuous furnace

- Annealing furnace

- Forced convection furnace

- Programmable furnace

- Air circulating furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.