- Metrology - Laboratory

- Laboratory Equipment

- Tubular oven

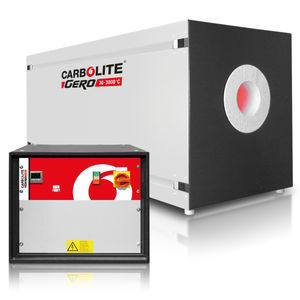

- Carbolite Gero

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Tubular furnace TSR seriesrotaryheat treatmentthermal

Add to favorites

Compare this product

Characteristics

- Configuration

- tubular, rotary

- Function

- heat treatment, thermal

- Heat source

- electric resistance

- Atmosphere

- controlled atmosphere

- Other characteristics

- continuous, horizontal, laboratory

- Maximum temperature

1,150 °C

(2,102 °F)- Width

3,150 mm

(124.02 in)- Height

1,830 mm

(72.05 in)- Depth

700 mm

(27.56 in)

Description

Carbolite Gero's TSR rotating tube furnace range incorporates the same innovations developed for the TS split tube furnace series with the equipment required to process large batches of free-flowing material, such as powders.

The TSR range comprises a split tube furnace horizontally mounted on a base frame, and fitted with a friction drive rotation system, allowing for work tube rotations of up to 10 rpm. The frame can be manually tilted up to a maximum angle of 6˚ to suit the requirements of the material being processed.

Accessory work tubes can easily be exchanged to meet the different physical or chemical requirements of a process.

Optional built-in gas systems enable users to equip the TSR rotating tube furnace for operation under a modified atmosphere.

Carbolite Gero's new tube furnace range is at the pinnacle of furnace design. The culmination of over 80 years of experience in thermal engineering; combining the latest technological developments with solid construction, high-quality components and a sleek, modern aesthetic.

The rotating motion of the TSR helps increase the surface area of the sample material exposed to the atmosphere within the work tube, helping to speed up reaction times and improve the overall yield. A 5 litre capacity vibratory feeder and corresponding collection hopper makes the TSR the ideal choice for continuous heat treatment processes.

HIGH QUALITY HEATING ELEMENTS

Excellent temperature uniformity

Fast heat-up and cool-down rates

Unsurpassed temperature uniformity along the entire heated length

HIGH QUALITY THERMAL INSULATION

Low energy consumption

Low external case temperature

Designed for longevity

VIDEO

Catalogs

Related Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Drying furnace

- Laboratory furnace

- Combustion furnace

- Gas furnace

- Baking oven

- Industrial furnace

- Controlled atmosphere furnace

- High-temperature furnace

- Automatic furnace

- Vacuum furnace

- Digital furnace

- Continuous furnace

- Annealing furnace

- Forced convection furnace

- Programmable furnace

- Thermal furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.