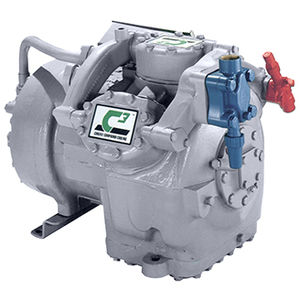

Open refrigeration compressor 5F, H seriespistonsingle-stagefor industrial refrigeration

Add to favorites

Compare this product

Characteristics

- Configuration

- open

- Technology

- piston

- Other characteristics

- single-stage

- Applications

- for industrial refrigeration

- Refrigeration capacity

Max.: 150 ch

(150 hp)Min.: 5 ch

(5 hp)

Description

Automatic unloaded starting, expensive high-torque motors are unnecessary, reducing initial expense.

High-efficiency motor can further increase efficiency of 5F and 5H compressors.

Crankcase casting, cylinder head, and valve plate designs allow for a smooth, unrestricted refrigerant flow.

Refined, two-piece shaft seal assembly virtually eliminates seal leakage for maximum reliability over a wide temperature range.

Efficient crankcase heater design prevents accumulation of liquid refrigerant in the crankcase during shutdown, dilution of the compressor oil supply.

As suction pressure changes, capacity control automatically reduces compressor capacity to as low as 35% of full-design load, reducing horsepower requirements as demand changes. Part-load operation increases energy efficiency, reducing utility bills.

Large-capacity, manually reversible oil pump, automatic pressure regulator, and oil-filtering system provide positive pressure lubrication, extending life.

Suction gases flow around cylinder sleeve to keep the cylinder cool, reducing cylinder wear.

Greater operating efficiencies by running an oversized compressor at a reduced RPM

Catalogs

5F/H Open-Drive Compressors

4 Pages

Related Searches

- Refrigeration compressor

- Piston refrigeration compressor

- Semi-hermetic refrigeration compressor

- Industrial refrigeration refrigeration compressor

- Single-stage refrigeration compressor

- Screw refrigeration compressor

- Commercial refrigeration refrigeration compressor

- Open refrigeration compressor

- Two-stage refrigeration compressor

- Twin-screw refrigeration compressor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.