- Materials - Tools - Components

- Standard Mechanical Component

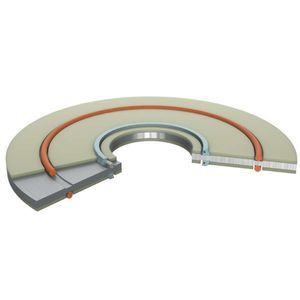

- Flange seal

- Carrara Global Sealing Solution

Flange gasket Guardian Basic seriesflangeflangeflange

Add to favorites

Compare this product

Characteristics

- Application

- flange, flange, flange, flange, for insulation pins, sleeve

Description

The flange insulation set Guardian Basic IPT uses Planiflon® B13 as sealing and insulation part. B13 it is the modified and bi-directionally oriented PTFE that minimizes the effects of relaxation typical of these gaskets, ensuring great reliability even in the most severe applications. Planiflon® B13 is applicable on the RF and FF flanges, guaranteeing a wide chemical compatibility, extended to the whole pH range 0 ÷ 14 with the exception of the few fluids for which the glass filler is not compatible. The flange isolation kit Guardian Basic IPT is applicable up to 200 ° C in ANSI ratings#150 - 300 and EN ratings# PN6-40. It is always recommended to use Sleeves and Washers in GRE G10 (FR4) - Glass Reinforced Epoxy Resin Composite materials - because compared to other materials, and in particular to phenolic material, the GREs have lower hygroscopic factor. This allows the seal to remain in service for the expected time without malfunctions due to the loss of mechanical load because the deterioration of the washers occurred.

Composition

The flange insulation set Guardian Basic ICSF uses Planiflex® PF64 like sealing and insulating material. This gasket is made by aramid-based materials and NBR rubber, specially selected to meet high performance standards for a wide range of industrial applications . Planiflex® PF64 can be applied at the temperature -40 ° C to 250 ° C and at the pressure classes 150-600 lbs and PN40. These gaskets show the typical chemical compatibility of the nitrile rubbers in the pH range . Planiflex® PF64 is applicable for sealing with vapors, lubricants, solvents, gases, steam and many diluted acids and alkalis.

Catalogs

INSULATION KITS

24 Pages

Other Carrara Global Sealing Solution products

FLANGE ISOLATION KITS

Related Searches

- Polymer seal

- Mechanical seal

- O-ring gasket

- Circular gasket

- Pump mechanical seal

- Metal seal

- PTFE gasket

- Metal mechanical seal

- NBR seal

- Round gasket

- Flat gasket

- Spring mechanical seal

- Gasket sheet

- Rubber gasket

- Cartridge mechanical seal

- Balanced mechanical seal

- Mechanical seal for the chemical industry

- Braided graphite packing

- Braided PTFE packing

- Stainless steel gasket

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.