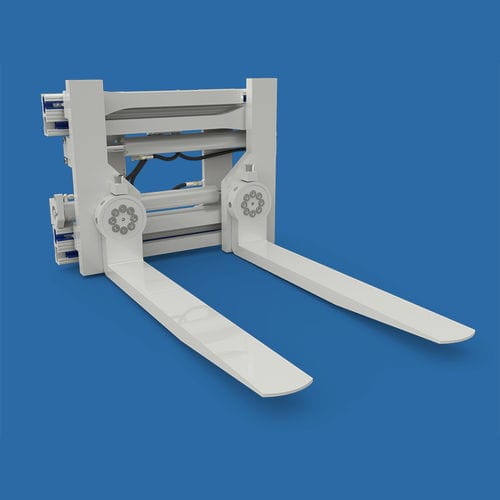

Cascade’s TURNAFORK™ is used in a variety of manufacturing, receiving, warehousing and shipping environments that require both clamp handling and pallet handling. Rotate the arms to the vertical position for clamping, or to the horizontal position to handle most types of conventional pallets. Order picking layers of varied product onto a pallet is simplified. In addition to clamp handling of cartons, the versatile TURNAFORK™ is also used for clamping awkward or difficult loads such as large tires.

Features

• Industry-leading visibility.

• Efficient hydraulic system which minimizes energy consumption and maximizes performance.

• Clamp and backhand protection.

• Flow divider for equal arm movement.

• Top-mounted hydraulic cartridges and test port for ease of access and adjustment.

• Sideshift circuit relief optimizes sideshift speed and performance.

• Rugged design for optimal strength, durability and performance.

• Center mounted hardened replaceable frame wear segment.

• (Except for revolving models).

• High strength steel frame.

• Lubrication-free, full length UHMW bearings.

• High strength steel castings.

• Maximum clamp force for secure handling.

• Designed for convenience and performance.

• Integrated true centering key for precise and secure installation.

• Available in two pressure offerings to match attachment to truck

hydraulic system.

Options

• Special frame widths and opening ranges.

• High pressure and low pressure hydraulics systems.

• Basic, sideshifting and revolving (360°) models available.

• Other arm dimensions.

• Independent arm control.

• Regeneration valve (faster opening speed for low flow electric trucks).