Simulation software PLO5DcontrolCAMverification

Add to favorites

Compare this product

Characteristics

- Function

- simulation, control, CAM, verification

- Applications

- process

Description

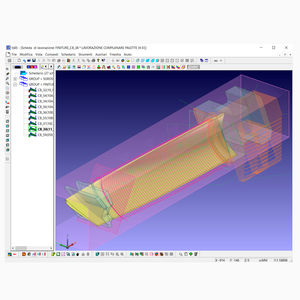

TOOL-PATH AND MATERIAL REMOVING SIMULATION

Based on a pre-defined or imported blank model and being loaded the tool path, one single process lead to the final shape of the machined part.

STL MODELS COMPARISON

PLO5D is able to compare the shape of the machined part resulting from the tool path and material removing simulation against a pre-loaded STL reference model. Differences can be easily highlighted and measured.

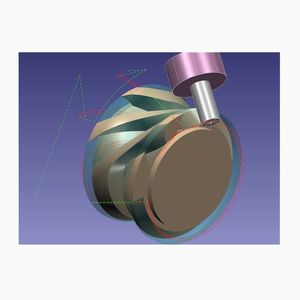

COLLISION CONTROL

PLO5D features an accurate collision control between all the machine parts like electrospindle, dividing heads, fixtures and any other component specified by the user.

The PLO5D software is a full simultaneous 5 Axis “verification” tool that simulates and check the tool path generated by the CAM prior to start the machining operation. It is widely used by our customers to check the machining programs and the related material removal process, in order to detect any possible defect, avoid errors and prevent collisions. Unlike most verification software available on the market, PLO5D has been developed to create a very accurate model, without a pre-defined precision tolerance limit, giving it the ability to predict the smallest imperfections on the machined part.

Catalogs

No catalogs are available for this product.

See all of CB Ferrari‘s catalogsRelated Searches

- Automation software solution

- Process software solution

- Control software solution

- 3D software solution

- Simulation software

- Programming software

- CAM software

- Milling software

- Verification software

- Engraving software

- Software for welding applications

- Machining center software

- Laser machining software

- Laser cutting software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.