Database software CALMconfigurationCAMlaser machining

Add to favorites

Compare this product

Characteristics

- Function

- database, configuration, CAM

- Applications

- laser machining, engraving

- Type

- 3D

Description

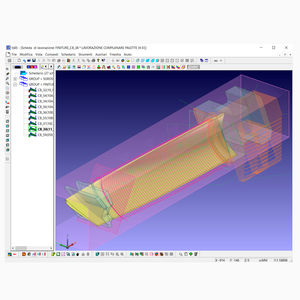

PREVIEW OF THE LASER PATHS

It is possible to have a preview of all the laser scan line and machine movements with an estimation of the working time

AUTOMATIC ROUTINE FOR LASER PARAMETERS SETTING

In order to check the effect of the laser on the material there is a special function that generates an automatic test with a combination of different laser parameters

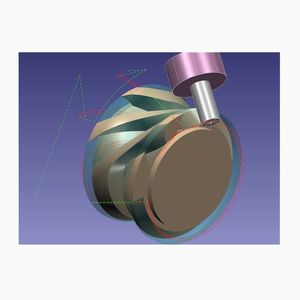

TSP ALGORITHM

The algorithm Traveling- Salesman is integrated in the software in order to reduce the machine displacement on 3D engraving on complex features

JUNCTION DEFECTS REDUCTION

A special algorith to reduce the typical joining defects in multi displacement laser engraving is implemented and tested inside the software.

CUSTOMIZATION

Interface, input and output are customizable on the basis of the customer request

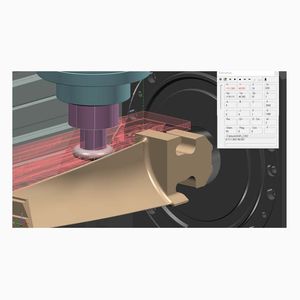

CALM (Computer Aided Laser Manufacturing) is a sophisticated CAM software dedicated to laser machining. The software is used for laser marking, deep-engraving and texturing on surfaces for different applications (aerospace, automotive, precision components, electronics, watch and jewelry, die and moulds). The software is fully integrated inside C.B. Ferrari laser systems. It produces, according to the user-defined modes, all the necessary instructions for the machines in order to realize the final workpiece. The geometrical data are imported generally through the DXF, STL, OBJ, BMP or IGES formats stored in the internal geometrical database. The laser engraving is performed through several steps including geometry check and repair, laser parameters selection, scan head and machine configuration. The program offers a complete set of engraving strategies.

Catalogs

No catalogs are available for this product.

See all of CB Ferrari‘s catalogsRelated Searches

- Automation software solution

- Process software solution

- Control software solution

- 3D software solution

- Simulation software

- Programming software

- CAM software

- Milling software

- Verification software

- Engraving software

- Software for welding applications

- Machining center software

- Laser machining software

- Laser cutting software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.