Database software TS115configurationCAMfor welding applications

Add to favorites

Compare this product

Characteristics

- Function

- database, configuration, CAM

- Applications

- for welding applications, for laser cutting

Description

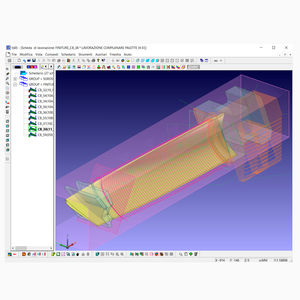

PREVIEW OF THE LASER PATHS

It is possible to have a preview of all the laser movements with an estimation of the working time

ADVANCED FUNCTION SETTINGS

Repair function to close the gaps and the auto-intersections. Easy functions to invert rotation profile, draw profiles nodes, calculate barycenter, measuring distance.

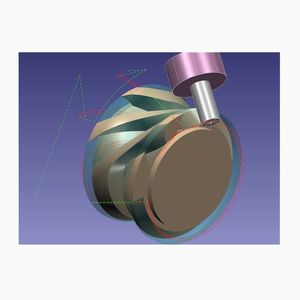

AUTOMATIC HOLES RECOGNITION

If the profiles are circles the software recognize its in automatic and permit to choose if

TSP ALGORITHM

The algorithm Traveling-Salesman is integrated in the software in order to reduce the machine displacement on presence of a very high number of profiles.

CUSTOMIZATION

Interface, input and output are customizable according to the customer request

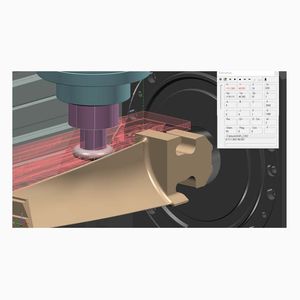

TS115 is a CAM software dedicated to laser cutting, welding and drilling. The software is used for different applications (aerospace, automotive, precision components, electronics, watch and jewelry, die and moulds). TS115 is fully integrated inside C.B. Ferrari laser systems. It produces, according to the user-defined modes, all the necessary instructions for the machines in order to realize the final workpiece. The geometrical data are imported generally through the DXF or IGES formats stored in the internal geometrical database. There is also a module for laser cutting of letters with fonts and geometrical dimensions defined by the user. The laser cutting/welding/drilling is performed through several steps including geometry check and repair, laser parameters selection and machine configuration. The program offers a complete set of laser strategies. TS115 enables our customers to produce efficient laser processes, allowing lower costs.

Catalogs

No catalogs are available for this product.

See all of CB Ferrari‘s catalogsRelated Searches

- Automation software solution

- Process software solution

- Control software solution

- 3D software solution

- Simulation software

- Programming software

- CAM software

- Milling software

- Verification software

- Engraving software

- Software for welding applications

- Machining center software

- Laser machining software

- Laser cutting software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.