- Industrial machines and equipment

- Heat Exchanger and Refrigeration

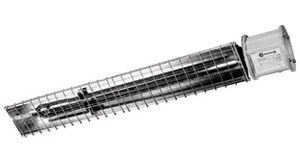

- Tubular heating element

- CCI Thermal Technologies Inc.

Tubular heating element KX seriesflexiblefinned

Add to favorites

Compare this product

Characteristics

- Type

- tubular, finned

- Maximum temperature

300 °C

(572 °F)

Description

The Caloritech™ KX Finned Tubular Heater (Calrod® type*) is typically manufactured to custom specifications based on the customer application, where steel fins are spirally wound over a heating element and then metallurgically bonded by furnace brazing, leaving negligable thermal resistance at the joint.

They are normally used for forced convection heating applications with outlet air temperatures up to 300°C (572°F), such as forced circulation, air or gas heating systems like ducts, fan forced electric heaters, recirculating ovens and loading resistors. Finned tubular heaters offer distinct advantages over open coil heaters, including minimized risk of fire or electrical shock, longer service life and less overall required maintenance.

Features & Benefits At A Glance

Various combinations of fin thickness, width and pitch available depending on requirements

Four surfaces finishes available: bare steel, nickel plated, aluminum painted and black enamel

Operating temperatures will vary depending on air velocity, air temperature and watts per square inch

Standard element diameters range from 0.260" to 0.540" (7 mm to 14 mm)

Watt density of 10 W / sq.in on standard heaters; custom watt densities are available for lower velocities or higher outlet temperatures upon request

Installation using brazed, crimped or welded plates; standard units have have factory installed fittings for this purpose

Catalogs

No catalogs are available for this product.

See all of CCI Thermal Technologies Inc.‘s catalogsOther CCI Thermal Technologies Inc. products

Caloritech™

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.