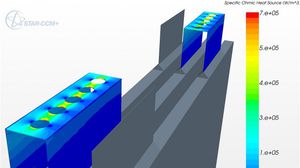

Simulation software STAR-CASTfor molding

Add to favorites

Compare this product

Characteristics

- Function

- simulation

- Applications

- for molding

Description

The increasing demand from consumers for newer, cheaper and more efficient products is increasingly influencing the way products are designed and produced. Virtual manufacturing processes are recognized to be part of the solution to deliver better products. This goes also for casted goods. To accommodate the ever changing placed upon casting processes simulation methods have to evolve as well. This means expanding the simulation scope both in terms of the complexity of the replicated boundary conditions and processes as well as the detail in which physical modelling is done. An overall understanding of the solidification pattern, possible defect distribution must be understood in order to design the casting process efficiently. This also includes that its micro structure is in the specified range, so that structural requirements can be met.

Catalogs

No catalogs are available for this product.

See all of CD-adapco‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.