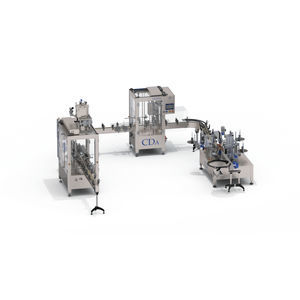

Automatic filler capper labeler

Add to favorites

Compare this product

Characteristics

- Operating mode

- automatic

Description

CDA offers comprehensive lines (filling, capping, and labelling) perfectly suited for the packaging of spirits. Among our range of solutions, the machines most commonly used in distilleries are as follows:

• - The K-Line S linear filler. Enclosed, easy to use and adjust, it remains versatile and offers excellent cleanability. Depending on the nature of your products, we adapt the dosing system to meet your needs, whether it’s volume measurement with one or multiple pistons, or flow measurement, with or without the use of a pressurised buffer tank. With the K-Line S, you can package up to 3000 litres per hour, maintaining an accuracy of +/- 0.5% of the dosed volume.

• - The VST automatic capper stands out for its versatility and ease of use, offering automatic distribution and capping of T-corks. Equipped with an elevator, it transports the corks to an orientation bowl that distributes them automatically (in the correct direction) onto a ramp. This ramp then ensures the automatic distribution of the corks at the bottle’s neck. The elevator is a standard element, offering greater autonomy and simplifying the operator’s work. With a capacity of up to 1800 corks per hour (depending on the cork type), the VST ensures maximum efficiency.

Catalogs

No catalogs are available for this product.

See all of CDA‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Automatic filler

- Liquid filler

- CDA automatic labeler

- Filler for the food industry

- Bottle filler

- Food product filling machine

- CDA bottle labeler

- Volumetric filler

- Semi-automatic filler

- Multi-head filler

- Filling system for the chemical industry

- CDA side labeler

- CDA labeler for the food industry

- Filler for the cosmetics industry

- CDA labeler for the pharmaceutical industry

- CDA labeler for the cosmetics industry

- Complete packaging line

- Top labelling machine

- Piston filler

- Container filler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.