- Products

- Catalogs

- News & Trends

- Exhibitions

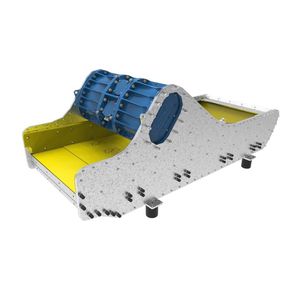

Process screening unit R seriesconstructionfor industryfor recycling

Add to favorites

Compare this product

Characteristics

- Applications

- construction, for recycling, for industry, process

- Type

- stationary

- Material

- for bulk materials

- Other characteristics

- 2-deck, single-deck

Description

Unique design delivering unrivalled protection of your downstream process. If you've got tough to handle material then you need the patented* R-Series feed conditioning system to get the most out of your processing equipment.

TOUGH. CLEVER. VERSATILE

From clay bound gravel, rock and mineral ores to sticky construction, demolition & excavation waste and mine overburden the patented R-Series makes it easy to maximise product yield from your feed material.

FEED POINT FLEXIBILITY

The hopper design allows the R-Series to be fed from all sides - ensuring easy integration into your existing plant or a site with minimal space. The patented R-Series has also been designed to accommodate feeding from loading shovels as well as direct feed from tipper trucks.

VIBROCENTRIC DRIVE

The unique construction of the VibroCentric drive removes unnecessary weight while delivering acceleration up to 5G for enhanced screening performance. A single sealed unit, the drive system is protected from material and water ingress to ensure maximum equipment life and allows you to continue to meet and exceed your production targets.

MAXIMISE PRODUCTION TIME

The SKF Explorer and Timken spherical roller bearings are rated for up to 70,000 hours and these are double sealed, eliminating potential for water or material ingress and maximising production time.

TRANSFER POINT EFFICIENCY

Your patented R-Series is designed to seamlessly integrate with the other modular equipment in our range, or indeed other washing equipment to ensure maximum transfer point efficiency.

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.