- Products

- Sand attrition unit

- CDE Group

- Products

- Catalogs

- News & Trends

- Exhibitions

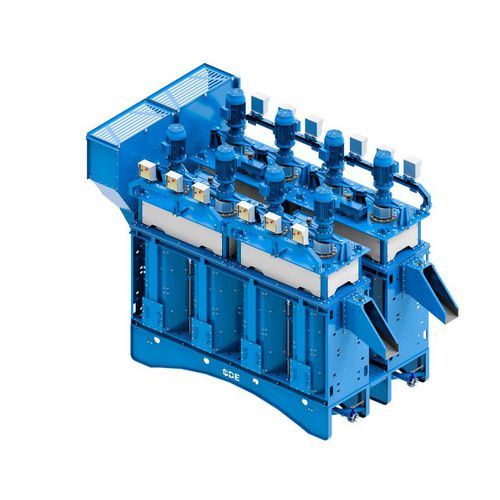

Sand attrition unit SHEARCLEAN™ series

Add to favorites

Compare this product

Characteristics

- Material

- sand

Description

UNRIVALLED CONTAMINANT REMOVAL

Efficient removal of contaminants from your fine material feed ensures the production of consistently graded material, allowing you to maximise the efficiency of your downstream production processes.

CONSISTENT MATERIAL SCRUBBING

Paddle design increases attrition towards the tank periphery ensuring consistent scrubbing for all your material and maximises material on material impact for the most efficient scrubbing performance.

REDUCED OPERATIONAL COSTS

ShearClean™ offers you a high specific capacity requiring less power, reducing your running costs and maximising the efficiency of your processing plant. ShearClean™ utilises 30kW motors where others require 50kW to enable start up under full load. Soft start reduces power requirement at start up and extends motor life by reducing load stress.

BUILT TO LAST

The patented ShearClean™ attrition cells are packed with features and design innovations which ensure your machine will stand the test of time.

• In-Line Gearbox: The in-line configuration of the ShearClean™ gearbox eliminates cantilever load to maximise the working life of your attrition cells.

• Planetary Gearbox: ShearClean™ attrition cells feature a planetary gearbox – compact and low weight with a high power density and maximum equipment life.

• Rubber Lined Cells: Individual cells fitted with rubber linings to protect your unit and minimise the time required for essential plant inspection and maintenance.

• Oil Cooling System: Prevents the unit from overheating, ensuring maximum equipment availability and allowing you to meet and exceed your production targets.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.