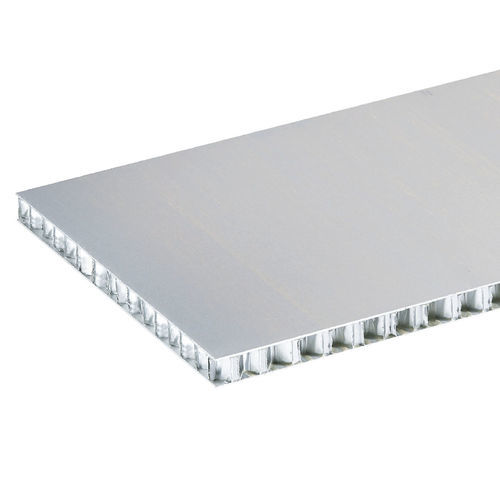

COMPOCEL® AL is a sandwich panel with a core in aluminium honeycomb bonded to two skins of aluminium. A panel entirely in aluminum. It offers high mechanical properties, perfect when high rigidity and a low weight are required. Being a panel made of 95% aluminum, the fire reaction properties meet the reference standards for numerous applications.

APPLICATIONS

COMPOCEL AL panel is used in countless sectors: building to shipbuilding, from railways to interiors, from cabins to lifts etc .... Customers can customize the panel according to their needs as it is a 100% customizable product.

PROCESSING

- CUTTING, SAWING, DRILLING AND SHAPING

These mechanical processes are performed by a programmed CNC. CEL is able to produce customized shapes, holes and processing, according to costumer's specifications.

- JOINING AND FIXING

Some projects require an anchoring system to fasten panels to other surfaces.

Cel offers different options:

panels attached to each other by visible or blind rivets and screws;

fixing with self-tapping screws (sealing washers) in aluminium or stainless steel

fastening with drilling screws.