- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

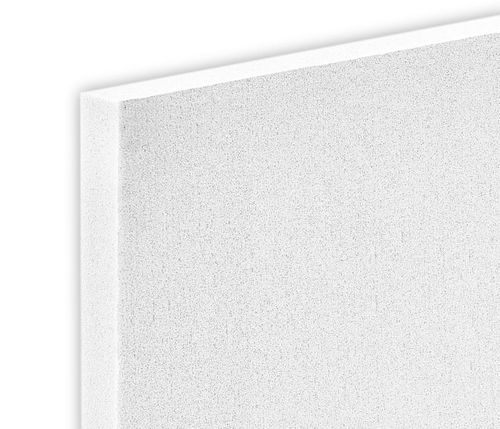

Foam PMI

Add to favorites

Compare this product

Characteristics

- Shape

- foam

Description

PMI (polymethacrylimide) is a foam developed specifically for use as a structural core in connection with vacuum infusion processes. It is applied in components for various sectors including aerospace and sports equipment with resin injection to reduce weight.

The PMI core allows sandwich panels to be produced in a single step (co-polymerisation), resulting in shorter overall production times. It is highly suitable for autoclave technologies and vacuum infusion processes, including RTM (resin transfer moulding) and VARTM (vacuum resin transfer moulding).

The cells of this foam have particularly small diameters in relation to other structural foams. This material achieves an optimal compromise between low resin absorption and satisfactory adhesion of the skins to the core.

Catalogs

No catalogs are available for this product.

See all of Cel Components S.r.l.‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.