Solvent pump Magmo series manually-controlledgearstationary

Add to favorites

Compare this product

Characteristics

- Fluid

- for solvents

- Operation

- manually-controlled

- Technology

- gear

- Mobility

- stationary

- Domain

- industrial

- Applications

- discharge

- Other characteristics

- suction

Description

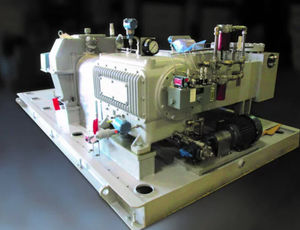

Sugar Pump - Magmo Series

Product Category:

MAGMO

Plenty Magmo sugar pumps are designed principally to handle high viscosity abrasive sugar products, such as Molasses, Massecuite and Magma. The ellipse and scraper principle it uses was originally devised by the sugar industry itself to overcome the problems associated with pumping these difficult liquids.

The current design includes the best features from previous pumps and successfully deals with the problems common to pumping liquids such as massecuite.

PRINCIPLE OF OPERATION

An elliptical shaped rotor rotates in a cylindrical housing, and carries round with it chambers of fluid. A hinged sealing arm, which follows the surface of the rotor, scrapes off the liquid and directs it up to the discharge port. As the chamber returns to the suction port it is re-filled by further liquid flowing in.

BEARING AND SEALING ARRANGEMENT

The bearing and sealing arrangement has been designed to deal with the wear and leakage problems associated with high viscosity abrasive duties. The bearing bushes are divided into an inner and outer portion.

The inner portion forms a general divider between the liquid in the pump and the grease in the bearing. The outer portion, which has longitudinal grooves, forms the bearing.

Greasing the bearing is a flushing operation and consists of introducing fresh grease at the outer end of the bearing and displacing contaminated grease through a drain at the inner end.

Catalogs

No catalogs are available for this product.

See all of CELEROS‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.