- Industrial machines and equipment

- Mixing and Dosing

- Liquids dosing dispenser

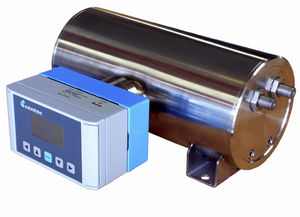

- Centec Gesellschaft für Labor- und Prozessmesstechnik mbH

Liquids dispensing system 10 - 150 000 l/h | ADoS volumetricautomated

Add to favorites

Compare this product

Characteristics

- Product

- liquids

- Type

- volumetric

- Other characteristics

- automated

Description

The Additive Dosing System is a very flexible system for the continuous and fully automated dosing of one or several components into a main stream.

With this In-line dosing system, soft drinks, beer mix drinks or other liquids can be produced economically optimized. Also, the system can be designed for direct dosing of additives in CIP units etc. Small amounts can be dosed into each other with the same precision as higher volume streams.

The Centec Additive-Dosing Unit allows an economically optimized production by maximum utilisation of the available capacities. The direct dosing of raw materials in one procedure step, as well as the correction of the concentration value of additives are possible. Using high accurate flowmeters as well as pneumatic control valves and adjustable displacement pumps, the volume relation or mass relation is continuously adjusted to the main flow - additive. Optional storage tanks or containers as well as customized drums can be integrated into the system. Several additives about different inlets can be dosed at the same time. The storage containers can be heated or be provided with a stirrer for mixing. The cleaning of the unit takes place alternatively with the CiP cleaning of the main line or separately. If requested the unit can combined with other modular systems, as for example water deaeration or carbonation etc.

Catalogs

No catalogs are available for this product.

See all of Centec Gesellschaft für Labor- und Prozessmesstechnik mbH‘s catalogsOther Centec Gesellschaft für Labor- und Prozessmesstechnik mbH products

Food & Beverage Industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.