- Industrial machines and equipment

- Surface Treatment Equipment

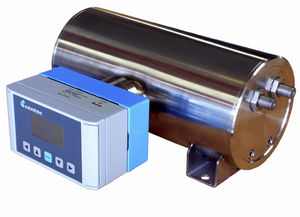

- Clean-in-place unit

- Centec Gesellschaft für Labor- und Prozessmesstechnik mbH

CIP unit 100 - 20 000 l/h | CIP

Add to favorites

Compare this product

Description

The Centec CIP units are very flexible systems for the fully automated cleaning of production facilities. Product leftovers and coats are removed to archive a clean biologically and physically surface. Therefor the Centec CIP systems are optimized regarding the amount of used cleaning liquid, temperature, concentration and process circulating time . CIP stations can integrated at a central place (i.e. ideally in the center of a building or the production plant, or decentralized (beside the specified production units). The cleaning liquids are rejected after the use (lost CIP) or can be re-use if stored (batch CIP).

For the execution of the cleaning process, different components as for example tanks, pumps, valves, heat exchangers, PLC and control software are necessary to provide the cleaning liquids to the units to be cleaned. The units can be placed centrally for all production plants or decentralized, i.e. for part of the production units with the different capacities. The cleaning liquids can be used in circulation mode with suitable batch tanks or in direct consumption. The technical optimization of the process reduces the mixtures of the single cleaning liquid. According to the given procedure technology the cleaning capacities are customized and controlled concerning the necessary speed.

Catalogs

No catalogs are available for this product.

See all of Centec Gesellschaft für Labor- und Prozessmesstechnik mbH‘s catalogsOther Centec Gesellschaft für Labor- und Prozessmesstechnik mbH products

Food & Beverage Industry

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.