- Hydraulics - Pneumatics

- Filter and Separator

- Cartridge filter housing

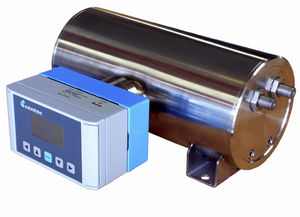

- Centec Gesellschaft für Labor- und Prozessmesstechnik mbH

Cartridge filter housing INTRAP for liquids

Add to favorites

Compare this product

Characteristics

- Filter type

- cartridge

- Fluid

- for liquids

Description

Get high security for the liquid process with the Centec InTrap system.

Integrated in the production, equipped with an optional continuous differential pressure measurement, the InTrap System can be designed for many applications downstream Blending or Additive Dosing systems as trap back flushable filtration.

Single stage or multistage with redundancy minimises production stops.

The Centec Trapfilter system InTrap can be designed as a manually operated unit with pressure indicators or as a fully automated System with its own PLC. Using filter cartridges with optimised pore sizes increase the production time. Combined with an automated backflush system which is controlled by differential pressure measurement, the lifetime of the filters will be maximised. On request the InTrap system can be designed as a skid mounted unit. This minimises the installation work. Integrated in an existing process control system (SCADA) the quality management gets higher transparency about the production,

The system meets all hygienic standards and is fully integrated in the CIP cleaning process.

Catalogs

No catalogs are available for this product.

See all of Centec Gesellschaft für Labor- und Prozessmesstechnik mbH‘s catalogsOther Centec Gesellschaft für Labor- und Prozessmesstechnik mbH products

Food & Beverage Industry

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.