- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Belt brush SPZcleaningconveyorsurface treatment

Add to favorites

Compare this product

Characteristics

- Configuration

- belt

- Function

- surface treatment, cleaning, conveyor

- Material

- rubber

- Other characteristics

- modular, V-belt

- Diameter

Min.: 63 mm

(2 in)Max.: 450 mm

(18 in)

Description

Belt brushes are a variety of industrial brushes defined mainly by having a base consisting of a strap to which the tresses are inserted on one side.

At Sacema we manufacture belt brushes by combining the main advantages of traditional belts for the transmission of movement with the surface treatment provided by brushes.

Belt brushes are configurable in terms of size, shape, configuration and material of the filaments with which the industrial brush is defined.

Flat belt brushes

This is the most common application as the belt section is rectangular and can be open or closed depending on the application. Normally the belt is made of rubber. Its main application is for the transversal cleaning of conveyor belts and conveyor belts.

Toothed belt brushes

Very technical and specialised industrial brushes, as they are used only in those applications where synchronised work is required, where the positioning of the parts has to be precise and where the diameter of the pulley has to be small.

V-belt brushes

Very technical and specialised industrial brushes, as they are used only in those applications where resistance, working speed and robustness are required.

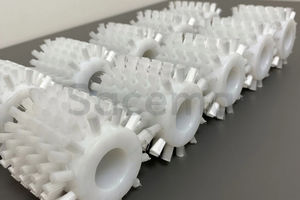

Band Brushes

A twist on the innovation of belt brushes is to make a conveyor belt out of them.

When you are looking to gently move parts, reduce noise or keep product clean as it travels on a belt. The system is made up of modular brushes, and sprockets to make the traction to suit the customer.

Catalogs

SHOE SOLE CLEANER

3 Pages

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.