- Production Machines

- Plastics Processing

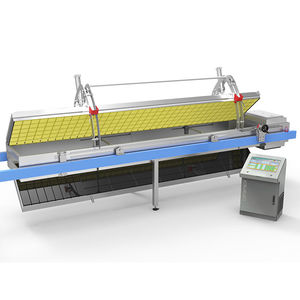

- Panel thermoforming machine

- Ceramicx Ireland Ltd.

Panel thermoformer

Add to favorites

Compare this product

Characteristics

- Type

- panel

Description

The Custom Skylights job Ceramicx with the challenge of a limited 208V 200 amperage power supply. A typical oven design of 96” x 100” would normally use 600 watt elements and require over 400 amps to power all the heaters.’

Ceramicx therefore chose to create a 300 watt hollow ceramic infrared heating emitter mounted in polished aluminized steel reflectors.

The Ceramicx 96 x 100 inch thermoforming heating system was designed with 12 individual control zones for maximum flexibility and production options. The entire oven and control system was pre-tested at Ceramicx and shipped to Weco International and then Custom Skylights. The oven was installed with predetermined mounting locations, power was landed to the control enclosure and the system was running.

The aluminized steel reflector provided better strength than aluminum, comparable reflectivity and a higher tolerance to heat than stainless steel. The overall design provided the best directional energy for Custom Skylights application. The 300 Watt hollow ceramic emitter stayed within the power requirements, the amp draw of the whole system was kept below 200 amps, and the new system provided the maximum directional energy to the material.

Catalogs

No catalogs are available for this product.

See all of Ceramicx Ireland Ltd.‘s catalogsRelated Searches

- Thermoformer

- Automated thermoforming machine

- Packaging thermoformer

- Roll-fed thermoformer

- Vacuum thermoformer

- Industrial thermoformer

- Sheet thermoforming machine

- Plastic film thermoformer

- In-line thermoformer

- Automotive part thermoforming machine

- Large part thermoforming machine

- PLC-controlled thermoforming machine

- Inner liner thermoforming machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.