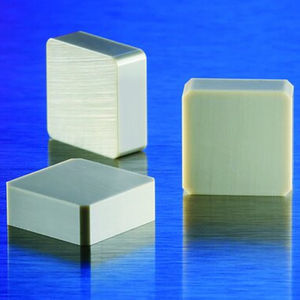

Solid milling cutter LSM 800faceplungeshoulder

Add to favorites

Compare this product

Characteristics

- Construction

- solid

- Type

- face, plunge, shoulder

- Material

- ceramic

- Other characteristics

- cutting

- Diameter

Min.: 6 mm

(0.24 in)Max.: 20 mm

(0.79 in)- Length

60 mm, 65 mm, 70 mm, 83 mm, 93 mm

(2.36 in, 2.56 in, 2.76 in, 3.27 in, 3.66 in)

Description

In the industrial segments of aerospace, power generation and oil and gas production, many components are made of heat-resistant materials such as nickel alloys or Inconel due to the required properties. The milling of Inconel and nickel alloys places high demands on the cutting material in terms of hot hardness and wear resistance - requirements that ceramic cutting materials optimally fulfil. As a result, the production speed and economic efficiency increase significantly.

The cutters are designed for a wide range of applications and can be used, for example, for milling pockets and grooves, for plunge milling, shoulder milling and ramp milling and, of course, for face milling.

Catalogs

No catalogs are available for this product.

See all of CERAMTEC‘s catalogsRelated Searches

- Milling tool

- Solid milling tool

- Steel milling tool

- Clamping milling cutter

- Insert milling tool

- Indexable cutting insert

- Cutting milling tool

- Face milling tool

- Roughing milling tool

- Helix angle milling cutter

- Shell-end milling tool

- High-performance milling tool

- Shoulder milling tool

- Turning indexable cutting insert

- High-precision milling tool

- Cutting tool

- CBN indexable cutting insert

- Turning insert

- Milling indexable cutting insert

- Cast iron indexable cutting insert

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.