- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

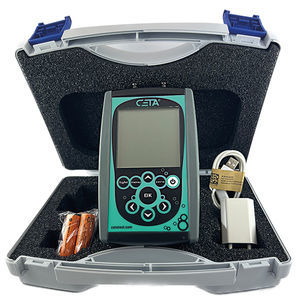

Differential pressure decay leak tester CETATEST 815 TWINpressure riseelectro-pneumaticfor automotive applications

Add to favorites

Compare this product

Characteristics

- Type

- differential pressure decay, pressure rise, electro-pneumatic

- Applications

- for automotive applications, for packaging, for plastics weldings, blister, for bottles, for vehicle pneumatic systems, for valves, for pipe, for oil filters, relay, for aeronautical applications, for the plastics industry, for automation, expansion tank, for sensors, for empty containers, for pipettes, for cans, for seal integrity, breathing apparatus and face mask, for injection valves, for empty aerosol cans, for vessels

- Other characteristics

- automatic, compact, USB, Profibus

Description

The dual-channel leak differential pressure tester CETATEST 815 TWIN allows simultaneous leak testing of two test pieces within the cycle time of the manufacturing process.

The differential pressure method compares the pressure in the test part volumes with the pressures in the reference volumes.

The CETATEST 815 TWIN is designed for synchronous two-channel operation and is suitable for applications in which test parts can be tested with the same settings. The channel specific adjustments of the leak thresholds are possible.

Parameters can be exported to an USB stick or imported again. It is also possible to save measurement series and measurement curves.

Sensors - Each channel has one gauge pressure sensor and one differential sensor

Pressure ranges - -1 bar, 200 mbar, 1 bar, 6 bar, 10 bar, negative gauge pressure and positive gauge pressure ranges can be combined (e.g. -1 bar / +1 bar), other pressure ranges on request

Measurement ranges - ± 500 Pa / ± 5.000 Pa (display resolution: 1 Pa, internal resolution: effective 0,01 Pa)

Result units - Pa, hPa, PSI, Pa/s, hPa/s, PSI/s, mbar • l/s, ml/min, ml/h, l/min, l/h, mmHg, mmWs, Torr

Pressure regulator - Electronical

Additional functions - Prefill, smooth filling, free programmable control valves

Dimensions - 345 mm x 145 mm (3 U) x 435 mm (W x H x D)

Two channel operation - As option available

Typical applications - Direct fillable parts

Catalogs

Related Searches

- Pressure gauge

- CETA leak tester

- Differential pressure indicator

- Digital pressure indicator

- CETA pressure leak tester

- Absolute pressure indicator

- CETA automatic leak tester

- Packaging leak testing device

- Calibration pressure indicator

- Test pressure gauge

- Laboratory pressure indicator

- Compact pressure indicator

- Bottle leak testing machine

- Leak tester for automotive applications

- Vessel leak testing device

- USB leak testing device

- CETA compact leak tester

- Digital leak testing device

- Relative pressure indicator

- Valve leak testing device

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.