- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

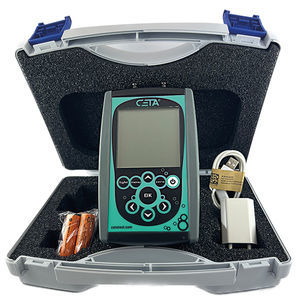

Absolute pressure decay leak tester CETATEST 715 LVelectro-pneumaticmass flowfor packaging

Add to favorites

Compare this product

Characteristics

- Type

- absolute pressure decay, electro-pneumatic, mass flow

- Applications

- for bottles, for packaging, for the plastics industry, for vessels, for automation, for IBC containers, expansion tank

- Other characteristics

- automatic, USB, Profibus

Description

The CETATEST 715 is a full automatically working leak tester for the detection of untight parts within the cycle time of the production process. The leak tester uses a gauge pressure sensor and has a large measurement range.

The CETATEST 715 is available in two variants:

The dual-channel variant CETATEST 715 TWIN allows simultaneous leak testing of two test pieces.

The CETATEST 715 LV (Large Volume) is suitable for the integral leak test of large-volume test parts (up to 1,000 l volume), such as bottles, canisters, drums, IBC (Intermediate Bulk Container).

Sensor type - Gauge pressure sensor

Pressure ranges - CETATEST 715 TWIN: -1 bar, 200 mbar, 1 bar, 6 bar, 10 bar

negative gauge pressure and positive gauge pressure ranges can be combined (e.g. -1 bar / +1 bar, -1 bar / +6 bar) | CETATEST 715 LV: 200 mbar

Measurement range - Max. +/-10,000 Pa, depending on the pressure range (resolution: 1 Pa)

Result units - Pa, hPa, PSI, Pa/s, hPa/s, mbar*l/s, PSl/s, ml/min, ml/h, l/min, l/h, mmHg, mmWs, Torr

Pressure regulator - Electronical

Test mode - Pressure decay test

Dimensions - 345 mm x 145 mm x 435 mm (W x H x D)

Typical applications - CETATEST 715 TWIN: Simultaneous leak test of two test parts.

CETATEST 715 LV: Leak test of large-volume containers and packages

Remark

All leak, mass flow and flow testers as well as pressure manometers and calibration standards (test leaks, master jets) are supplied with DAkkS-accredited and internationally recognized calibration certificate (compliant with DIN EN ISO/IEC 17025) as standard and at no extra charge on initial delivery.

Catalogs

Related Searches

- Pressure gauge

- CETA leak tester

- Differential pressure indicator

- Digital pressure indicator

- CETA pressure leak tester

- Absolute pressure indicator

- CETA automatic leak tester

- Packaging leak testing device

- Calibration pressure indicator

- Test pressure gauge

- Laboratory pressure indicator

- Compact pressure indicator

- Bottle leak testing machine

- Leak tester for automotive applications

- Vessel leak testing device

- USB leak testing device

- CETA compact leak tester

- Digital leak testing device

- Relative pressure indicator

- Valve leak testing device

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.