- Detection - Measurement

- Flow, Pressure and Level Measurements

- Pressure leak tester

- CETA Testsysteme GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

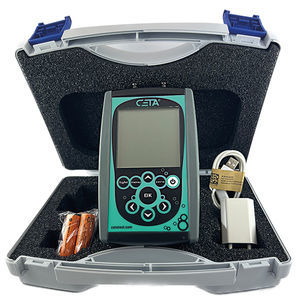

Pressure leak tester CETATEST 525automatic

Add to favorites

Compare this product

Characteristics

- Type

- pressure

- Other characteristics

- automatic

Description

The industrial PC controlled CETATEST 525 with 7" color touch screen and dual jog dial is a fully automatic leak tester for the detection of leaking parts within the cycle time of the production process. The differential pressure method is used here. This is based on comparing the pressures in the test part volume and in a leak-tight reference volume.

The use of fast-switching solenoid valves in combination with a very small internal measuring circuit volume makes the CETATEST 525 particularly suitable for very short test processes.

The CETATEST 525 is available in two different types:

The type “pressure decay measurement PD” can be used for leak tests of very small test parts in high speed production. The configuration “sealed components - high resolution SC HR” can be used for test parts which cannot be filled, so called “sealed components”. It is possible to detect very small ratios of test part volumes (0.03 ml < ΔV < 1.0 ml).

More than one million measurement results can be stored in the test device and over 256 individually parameterisable test programs with alphanumeric designation are available.

Pressure sensors - Differential pressure sensor, gauge pressure sensor

Pressure ranges - -1 bar, 200 mbar, 1 bar, 6 bar, negative and positive gauge pressure ranges can be combined (e.g. -1 bar / +1bar)

Measurement ranges - ± 500.0 Pa / ± 5,000 Pa (internal resolution: effectively 0.01 Pa)

Variants - Pressure decay measurement PD / Sealed components - high resolution SC HR

Dimensions - W x H x D: 367 mm x 183 mm (4 U) x 435 mm

Catalogs

No catalogs are available for this product.

See all of CETA Testsysteme GmbH‘s catalogsRelated Searches

- Pressure gauge

- CETA leak tester

- Differential pressure indicator

- Digital pressure indicator

- CETA pressure leak tester

- Absolute pressure indicator

- CETA automatic leak tester

- Packaging leak testing device

- Calibration pressure indicator

- Test pressure gauge

- Laboratory pressure indicator

- Compact pressure indicator

- Bottle leak testing machine

- Leak tester for automotive applications

- Vessel leak testing device

- USB leak testing device

- CETA compact leak tester

- Digital leak testing device

- Relative pressure indicator

- Valve leak testing device

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.