- Machine-tools

- Cutting Tool

- External threading tool

- CHAIN HEADWAY

External threading tool internalinsert

Add to favorites

Compare this product

Characteristics

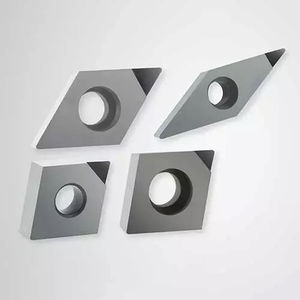

- Type

- external, internal

- Other characteristics

- insert

Description

We have more than two decades of experience in the design and manufacturing of CNC threading tools for global customers. All of our tools are designed and manufactured in house to deliver exceptional performance in CNC turning.

CNC thread turning is an operation which places high demands on the tools and requires excellent chip control and long tool life in order to deliver consistent performance in mass production environments.

CNC threading tools create the thread on the outside or inside diameter of the workpiece by making a number of passes across the surface to gradually cut the thread. The tip of the turning / threading tool must not be excessively stressed to avoid impacting thread quality and tool life.

Our CNC threading tools feature excellent tool life and are the industry standard for high volume production environments. Whether you are cutting an internal thread or an external thread, our tool designs deliver exceptional performance and tool life.

Our unique designs feature double coolant holes for highly efficient chip removal and extended tooltip life making these an economical and efficient choice for your production environment.

Our coolant fed tips drastically improve the ship removal efficiency compared to other designs and are especially useful when cutting inner thread in a deep hole where chip removal can be a challenge.

The accuracy of our tool inserts is vital to stable quality performance and we have invested in a full range of high precision optical imaging systems. The systems along with our dedicated internal inspection and quality team are able to meet the most rigorous inspection requirements.

Catalogs

No catalogs are available for this product.

See all of CHAIN HEADWAY‘s catalogsRelated Searches

- Milling tool

- Drilling tool

- Steel milling tool

- Solid drilling tool

- Metal milling tool

- Insert milling tool

- End mill milling tool

- Cast iron milling tool

- Indexable cutting insert

- General purpose drill bit

- Cutting milling tool

- Carbide drilling tool

- Aluminum milling tool

- Stainless steel milling tool

- Turning tool

- High-precision milling tool

- Insert turning tool

- CBN indexable cutting insert

- Milling indexable cutting insert

- Carbide indexable cutting insert

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.