- Packing - Handling - Logistics

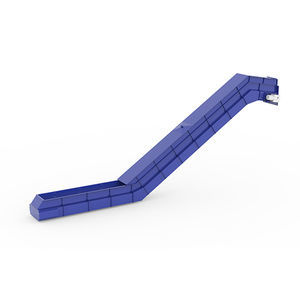

- Conveying

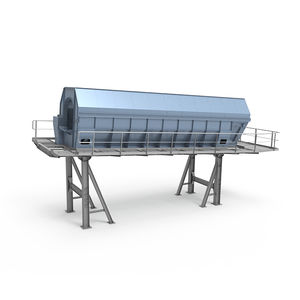

- Waste sorter

- Changzhou Jinyuan machinery equipment Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

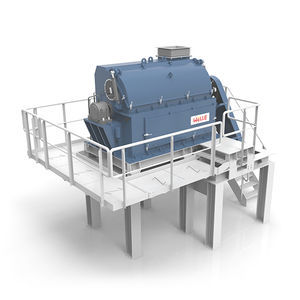

Cap sorting unit for wastefor separation units

Add to favorites

Compare this product

Characteristics

- Product applications

- for caps, for waste, for separation units

Description

The fine separation pulping machine has both crushing/pulping and sorting functionality. The materials enter from the feed inlet on top, and the sundries such as bottle caps, porcelain chips, small shells are screened out and discharged from the side outlet. The pulp after crushing and pulping by the wheel hammer is transported to the next process stage from the bottom outlet through the bottom extruder.

• Effectively remove small objects in the material such as porcelain chips, small shells, bottle caps and other solid materials.;

• The special pulping process can effectively cut the fiber in the bio-mass to the minimum (≤ 8mm), ensuring reliable organic slurry conditions for subsequent oil extraction and anaerobic process;

• Suitable for secondary fine sorting of homogeneous materials after large object sorting, so as to minimize the residue in the slurry that are harmful to the equipment, ensuring the service life of the equipment in the subsequent process, and reduce the pressure on the subsequent sediment system;

• Organic materials are made into slurry less than 8mm, which has less sediment content and high removal rate of sundries.

• The wheel hammer adopts a quick change structure, which is convenient for on-site replacement; The blades of the wheel hammer are treated, with good wear resistance and long service life;

• The main shaft is equipped with an impeller, which generates strong air flow under high-speed, making solid sundries drier.

• Lower consumption of power, the total installed power is less than 40kW, with processing capacity of 10t / h;

Application field:

Kitchen waste, household waste treatment, etc.

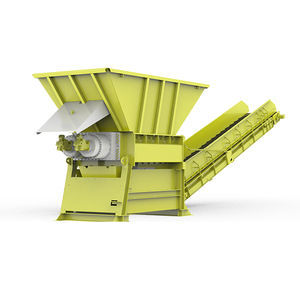

Other Changzhou Jinyuan machinery equipment Co., Ltd. products

Products

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.