Vehicle fleet management software optimizationdata usetelematics

Add to favorites

Compare this product

Characteristics

- Function

- vehicle fleet management, optimization, data use

- Applications

- telematics

Description

Fleet optimization – here’s why it matters

The lifespan of your fleet is dependent on running time, which affects everything from service intervals and leasing costs to second-hand value. So to maximize the return on your investment, you need to optimize your running time. And when it comes to fuel costs and CO2 emissions, they’ll remain the same – regardless of whether your machines are running productively (and creating value) or not. In the light of rising fuel prices: how is idling impacting your business today?

3 negative impacts of excessive idling:

Low productivity

Waste of resources

High environmental impact

Tackle excessive idling on two fronts

Removing idling altogether is not a realistic goal – but significantly reducing it is. To succeed, you need to tackle the issue on two fronts: by monitoring real-time data on fuel consumption and idling, while also motivating your frontline staff to change their behavior.

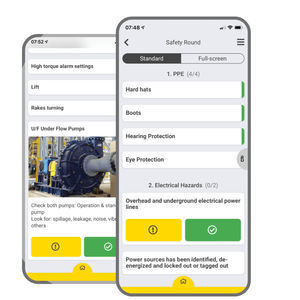

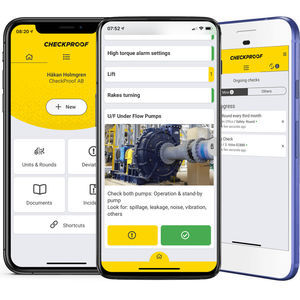

Leverage data through APIs and integrations

Let’s start with the data, since what doesn’t get measured cannot be improved. By streaming telematics data from your equipment manufacturers into your digital maintenance system, you can monitor fuel consumption and idle time across your fleet in real-time.

The data lets you compare results over time and between sites to track progress and discover where there’s room for improvement. This requires having the right APIs and integrations in place.

Use gamification to drive behavioural change

Let's face it: excessive idling comes down to bad habits. Leaving the engine running while waiting or taking a short break may not seem like a big deal.

VIDEO

Related Searches

- Automation software solution

- Management software solution

- Analysis software solution

- Windows software solution

- Control software solution

- Quality software

- Programming software

- Reporting software solution

- Optimization software solution

- Safety software

- Inspection software

- Construction software

- Android software solution

- Embedded software

- Quality control software solution

- Factory software solution

- Data use software

- Software for IIoT applications

- Telematics software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.