- Production Machines

- Plastics Processing

- Compounding extruder

- Cheng Yieu Development Machinery Co., Ltd.

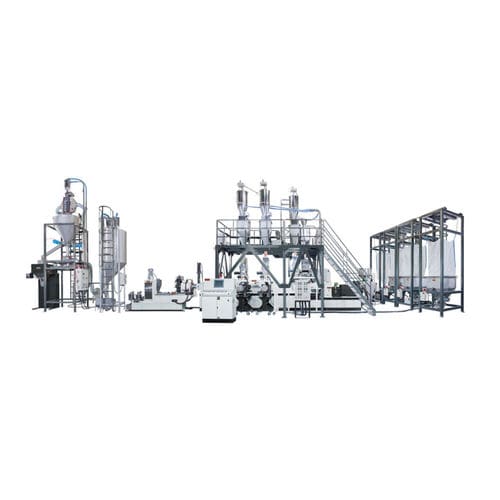

Compounding extruder CK-80HT co-rotating twin-screw

Add to favorites

Compare this product

Characteristics

- Applications

- compounding

- Number of screws

- co-rotating twin-screw

- Output

Max.: 950 kg/h

(2,094.3915 lb/h)Min.: 350 kg/h

(771.6179 lb/h)- Screw diameter

80 mm

(3.1 in)

Description

Description

CYKF is committed to the R&D and manufacturing of the automatic extrusion systems, and constantly strives for perfection. The CK-HT series Co-rotating Twin Screw Automatic Metering Weighing and Conveying Pelletizing Compounding Extrusion Line successfully overcomes the problem of customer limited site space and configures the optimal traffic line for customers. The high-efficiency system shows the advantages of safety, convenience, efficiency and quality, reflecting the greatest value of CYKF.

Possible materials :

TPU, PLA, PVA, SEBS, EVA, Hot-melt adhesive, Special resin, and Micro pellets, etc.

Features

1. High-output performance

The professional team of CYKF can design custom screws and barrels for extruder to achieve excellent mixing behavior based on its plentiful experiences in mechanism and plastic materials background. The high efficiency plastic extrusion machine brings outstanding pellet quality output to help customers have a rapid return on investment.

2. Human-machine interface control system

The features of high-level human-machine interface control system include program detection control, synchronized proportional speed control, remote monitoring, and production parameters adjusting.

3. Operator friendly

The co-rotating twin screw underwater pelletizing compounding extrusion line equipped with human machine automation system that controls every stage of the production processes from materials feeding, extruding, pelletizing, dehumidifying to storing. It is operator friendly and greatly saves manpower.

4. One-stop-shop service

CYKF provides complete plastic extrusion lines for customers.

Catalogs

CYKF Product Catalog

20 Pages

Other Cheng Yieu Development Machinery Co., Ltd. products

Compounding Pelletizing Line

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Pelletizer

- Screw extruder

- Twin-screw screw extruder

- Plastic pelletizer

- PVC extrusion line

- Waste granulator

- Single-screw screw extruder

- Polypropylen extrusion line

- Polyethylene extrusion line

- Compounding screw extruder

- PP screw extruder

- HDPE extrusion line

- PE screw extruder

- Twin-screw extrusion line

- ABS screw extruder

- PVC screw extruder

- Laboratory screw extruder

- PS screw extruder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.