- Production Machines

- Plastics Processing

- Compounding extruder

- Cheng Yieu Development Machinery Co., Ltd.

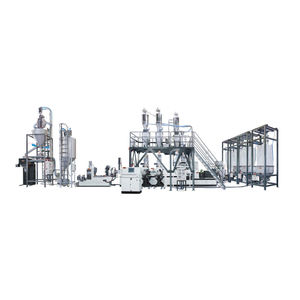

Extruder with underwater pelletizing CK-70HTcompoundingfor PPfor rubber

Add to favorites

Compare this product

Characteristics

- Applications

- compounding

- Treated material

- for PP, for rubber, for PS, for PLA, for EVA, for TPU

- Number of screws

- co-rotating twin-screw

- Other characteristics

- high-throughput, low melt temperature, with underwater pelletizing

- Output

Max.: 500 kg/h

(1,102.3113 lb/h)Min.: 250 kg/h

(551.1557 lb/h)- Screw diameter

71 mm

(2.8 in)

Description

CK-HT series Co-rotating Twin Screw Underwater Pelletizing Compounding Extrusion Line is designed especially for compounding materials with low viscosity, sticky, or difficult to shape. The extrusion line can be applied to a wide range of materials and applications.

Possible materials:

TPU, TPE, TPV, TPR, PP, PS, PLA, PVA, SEBS, EVA, Rubber, Hot-melt adhesive, Special resin, and Micro pellet, etc.

Features

1. Operator friendly

The co-rotating twin screw underwater pelletizing compounding extrusion line operates virtually automatically. No additional manpower is needed. Every step of the production process, from dosing, extruding, pelletizing to dehumidifying, all adjusted synchronously to maximize operation convenience.

2. High throughput

Our strong mechanism and plastic materials background enable us to design the specific screw and barrel for extruder to achieve excellent mixing behavior. The plastic extrusion machine brings high quality plastic pellets and higher throughput to let customers have a rapid return on investment.

3. One-stop-shop service

CYKF integrates complete plastic extrusion lines for customers. For the various demands of compounding, we provide integration and configurations of auxiliary equipment to solve customers’ problems, e.g., twin screw dosing feeder and side feeder. Our services range from equipment consulting, integration, installation, and maintenance. We make your work easier and quicker.

4. Durable and steady

Thanks to our strict policy in product quality that makes our extrusion lines durable and steady, some lines are still operating at customers' site even it has been in operation for more than 20 years.

Catalogs

CYKF Product Catalog

20 Pages

Other Cheng Yieu Development Machinery Co., Ltd. products

Compounding Pelletizing Line

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Pelletizer

- Screw extruder

- Twin-screw screw extruder

- Plastic pelletizer

- PVC extrusion line

- Waste granulator

- Single-screw screw extruder

- Polypropylen extrusion line

- Polyethylene extrusion line

- Compounding screw extruder

- PP screw extruder

- HDPE extrusion line

- PE screw extruder

- Twin-screw extrusion line

- ABS screw extruder

- PVC screw extruder

- Laboratory screw extruder

- PS screw extruder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.