- Production Machines

- Plastics Processing

- Pelletizing extruder

- Cheng Yieu Development Machinery Co., Ltd.

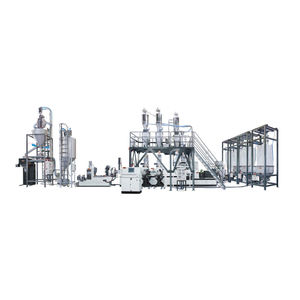

Pelletizing extruder CK-58HTfor PEfor WPCfor ABS

Add to favorites

Compare this product

Characteristics

- Applications

- pelletizing

- Treated material

- for PE, for WPC, for ABS, for PC, for PS, for PA66

- Number of screws

- co-rotating twin-screw

- Output

Max.: 450 kg/h

(992.0802 lb/h)Min.: 150 kg/h

(330.6934 lb/h)- Screw diameter

58 mm

(2.3 in)

Description

Description

CK-HT series Co-rotating Twin Screw Strand Pelletizing Compounding Extrusion Line is especially for composite materials that are suitable for strand pelletizing production method. It can be applied to a wide range of plastics.

Possible materials:

Various composite materials, e.g. PC, PE, PS, ABS, Nylon, LCP, PPS with additives of glass fiber, Wood powder, CaCO3.

The mixed materials are stably fed into extruder by dosing feeder. The materials are melted, kneaded, and extruded by plastic extruder. The extruded strands are immediately pulled into water tank for cooling, and then again pulled into strand dryer to remove moisture on pellet surface. Finally, the strands are cut into pellets by pelletizer and stored by storage tank.

• - Vertical mixer

The materials are completely, quickly, and evenly mixed by the helix. The stainless steel tank is not easy to leave material retention.

• - Dosing feeder

The twin screw dosing feeder operates with the mixer is able to stabilize materials feeding and increase production capacity at the same time.

• - Extruder screw

The screw zones of conveying, melting, mixing, compressing, venting, and vacuum are designed according to customers’ material formulations. From steel selection, machining accuracy to quality management, we have strict standard procedures to make sure the good quality and lifetime of these key components.

• - Die

The die material and mold runner must be selected and designed according to the physical properties and characteristics of plastics to avoid occurrences of uneven material flow rate, retention

Catalogs

CYKF Product Catalog

20 Pages

Other Cheng Yieu Development Machinery Co., Ltd. products

Compounding Pelletizing Line

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Pelletizer

- Screw extruder

- PVC extrusion line

- Twin-screw screw extruder

- Polypropylen extrusion line

- Plastic pelletizer

- Polyethylene extrusion line

- Waste granulator

- Single-screw screw extruder

- HDPE extrusion line

- Compounding screw extruder

- Extrusion line with water cooling

- PP screw extruder

- Twin-screw extrusion line

- PVC screw extruder

- Laboratory screw extruder

- PE screw extruder

- ABS screw extruder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.