- Materials - Tools - Components

- Standard Mechanical Component

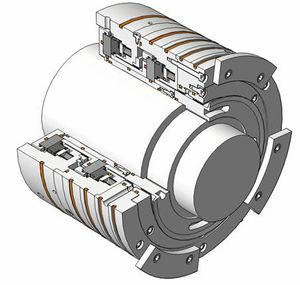

- Dual-cartridge mechanical seal

- Chengdu Yitong Seal Co., Ltd.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Dual-cartridge mechanical seal YTG801for pumpfor compressorsgas-lubricated

Add to favorites

Compare this product

Characteristics

- Type

- dual-cartridge

- Applications

- for pump, for compressors

- Other characteristics

- gas-lubricated

- Operating pressure

Min.: 0 Pa

(0 psi)Max.: 15,000,000 Pa

(2,176 psi)- Operating temperature

Min.: -104 °C

(-155 °F)Max.: 280 °C

(536 °F)

Description

Operating Conditions:

Pressure: 0~15.0MPa

Temperature: -104~280℃

Rotary speed: 1000~18000r/min

Linear speed: less than 160m/s

Applicable medium: media without pollution (air, CO2, N2, steam, etc.)

Material: stainless steel, rubber, graphite, carbon.

Design/Structure:

Adopt the advanced fluid dynamic pressure groove to assure the reliability.

Light material for rotary ring can reduce the sealing effect on the dynamic performance of the compressor rotor.

The labyrinth seal can guarantee the leakage of the medium not taken directly to the atmosphere

Non-contact operation

The cartridge seal is easy for installation and maintenance

Competitiveness:

High-performance, competitive price, prompt delivery and best service

Longer service life and low energy consumption

Can be customized according to customer’s requirement

More than 20 years' designing and manufacturing experience

More than 20 years’ vendor of Sinopec and PetroChina

Get the ISO9001, ISO14000 and ISO18000 certificate

Awarded a number of utility patents in researching and designing seals

Product Application:

Our products have been widely applied to petroleum, chemical fiber, fertilizer, oil refining, papermaking, nuclear power, power plant, metallurgy, food, pharmaceuticals, etc. Main products are mechanical seal, dry gas seal and all kinds of seal control systems, applying to rotating equipments.

Other Chengdu Yitong Seal Co., Ltd. products

gas-lubricated mechanical seal (dry gas seal)

Related Searches

- Mechanical seal

- Pump mechanical seal

- Metal mechanical seal

- Spring mechanical seal

- Cartridge mechanical seal

- Balanced mechanical seal

- Mechanical seal for the chemical industry

- Composite mechanical seal

- Bellows mechanical seal

- Sealing ring

- Shaft mechanical seal

- Stainless steel mechanical seal

- Process industry mechanical seal

- Multiple-spring mechanical seal

- Centrifugal pump mechanical seal

- Agitator mechanical seal

- Corrosive liquid mechanical seal

- Mechanical seal for the pharmaceutical industry

- Mechanical seal for the petrochemical industry

- Mixer mechanical seal

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.