- Industrial machines and equipment

- Welding and Assembly

- Reflow soldering machine

- Chengliankaida Technology.co.,LTD

- Products

- Catalogs

- News & Trends

- Exhibitions

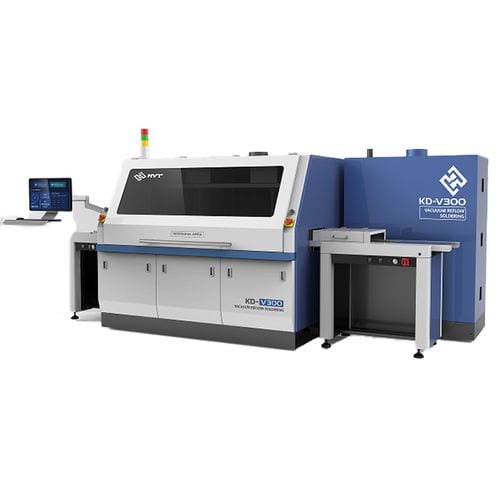

Reflow soldering oven KD-V300vacuumfor electronic componentsfor PCB

Add to favorites

Compare this product

Characteristics

- Technique

- reflow

- Operating mode

- vacuum

- Applications

- for PCB, for electronic components

- Power

Max.: 28,000 W

Min.: 8,000 W

Description

Our formic acid vacuum reflow oven be good at working for igbt power device with formic acid and nitrogen, effectively reduce the void rate , prevent the products from oxidation.

Features Of Void-Free Reflow Oven

• Void-free solder connections

• Soldering with preforms and/or pastes

• Process temperatures up to 300 °C

• Controlled temperature gradients

• Short cycle times

• Separate soldering and cooling chamber

• Flux-free soldering with formic acid

• Reproducibility of the soldering results

• Traceability

• Permanent process control

• Viewing system

• Independent temperature control system

KD-V300, as an automated online system for mass production, has been upgraded and optimized from Pink's VADU300KL/400X to the KD-V300. In comparison to Pink, we have the following advantages over them:

Temperature control advantage: Our product features 9 heating rods on the bottom heating plate, grouped into sets of 3, each with an independent control system. This effectively addresses the issue of low temperature at platform edges and a significant temperature difference between the edges and the center. As a result, our product provides more uniform heating, ensuring consistent temperature across the platform and improving soldering quality.

Flexible workflow: During the working process, if any issues arise, our machine automatically stops, allowing for problem analysis. If the problem does not affect soldering quality, operators can select any segmented process to continue the work, saving time and materials. In more serious cases, alternative materials can be selected directly. This flexibility enhances workflow efficiency and reliability.

Other Chengliankaida Technology.co.,LTD products

Vacuum Soldering system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.