- Machine-tools

- Finishing Machine

- Workpiece grinding machine

- CHEVALIER - Falcon Machine Tools

- Products

- Catalogs

- News & Trends

- Exhibitions

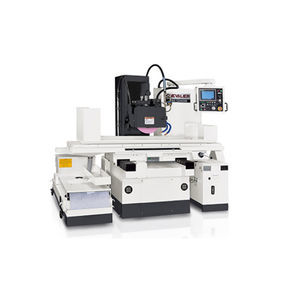

Workpiece grinding machine FVGC-40verticalCNC3-axis

Add to favorites

Compare this product

Characteristics

- Applications

- for workpieces

- Structure

- vertical

- Control type

- CNC

- Number of axes

- 3-axis

- Features

- stationary, direct-drive

- Other characteristics

- precision

- Spindle speed

10,000 rpm, 12,000 rpm

(62,832 rad.min-1, 75,398 rad.min-1)- X travel

520 mm

(20.47 in)- Y travel

368 mm

(14.49 in)

Description

-The FVGC Series of vertical grinding machine is easy setup, flexible and sealed to grinding.

-The axial protection design creates a completely sealed machine during the grinding operation.

-The worktable’s water-guided and waterproof design, which effectively prevents dust pollution, protects and increases the life span of precision transmission components.

-The coolant and filtering system filters and separates cutting chips, powder and impurity from the coolant liquid during the machining processes.

-The tool magazine’s automatic door provides fully enclosed dust-proof protection

-The optional fourth axis can be installed as the second spindle for rotary machining of ring-shape workpieces, with a stable and low-speed feed.

-Coolant-Through-Spindle System removes chips and heat from deep-hole machining and enhances tool cutting performance, longevity and parts accuracy.

-The double-row cutting fluid spray pipe function can form a water curtain to lubricate and cool the cutting points of various parts during processing.

-Spindle oil cooler can cool down the spindle temperature by constantly cycling the oil.

-The centrifugal filtration device uses high-speed, rotating centrifugation to separate the cutting fluid from dust.

-The water power filter or hydrocyclone system can filter and separate particles without the need to replace consumables.

-The graphical conversational software for this machine is a perfect match for this industry’s small batch production needs in the punch industry.

-An optional, table-mounted diamond roller dresser uses the graphic conversational function to grind different workpieces and perform grinding wheel dressing and compensation automatically

VIDEO

Other CHEVALIER - Falcon Machine Tools products

Grinding Machine

Related Searches

- Grinding machine

- CNC grinding machine

- Precision grinding machine

- Workpiece grinding machine

- Flat grinding machine

- High-precision grinding machine

- Automated grinding machine

- Vertical grinding machine

- Metal sheet grinding machine

- 3-axis grinding machine

- Stationary grinding machine

- Universal grinding machine

- PLC-controlled grinding machine

- High-performance grinding machine

- High-speed grinding machine

- 2-axis grinding machine

- Manually-controlled grinding machine

- Heavy-duty grinding machine

- Hydrostatic grinding machine

- Direct-drive grinding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.