- Machine-tools

- Finishing Machine

- Surface grinding machine

- CHEVALIER - Falcon Machine Tools

- Products

- Catalogs

- News & Trends

- Exhibitions

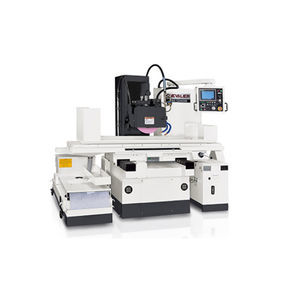

Surface grinding machine FSG-2 seriesfor workpiecestravelling columnautomatic

Add to favorites

Compare this product

Characteristics

- Type

- surface

- Applications

- for workpieces

- Structure

- travelling column

- Control type

- automatic

- Number of axes

- 3-axis

- Other characteristics

- high-precision, high-performance, heavy-duty

- Spindle speed

Max.: 2,200 rpm

(13,823 rad.min-1)Min.: 500 rpm

(3,142 rad.min-1)- Power

11 kW, 18.5 kW

(14.96 hp, 25.15 hp)- Distance between centers

730 mm, 850 mm

(29 in, 33 in)- Y travel

550 mm, 560 mm, 665 mm

(21.65 in, 22.05 in, 26.18 in)

Description

Chevalier's FSG-20/24ADIV Series of automatic precision surface grinders now includes four new machine sizes, along with several newly designed features: a traveling column structure to further reduce vibration and achieve higher accuracy; a spindle that can withstand heavy load grinding; and a double-V guideway for smooth, stable longitudinal movements. Fully supported worktable design. Maximum table speed: 30 m/min (98.4 fpm), which increases processing efficiency. Integrated machine-body temperature control system greatly improves accuracy and stability.

These four larger sizes, along with the entire FSG-20/24ADIV Series 3-axis automatic surface grinding machine, offer several design features to shorten processing and non-processing preparation while delivering high-precision workpieces: surface control, variable speed spindle, constant surface speed, smart grinding path and in-machine manual dynamic balancing.

The precision surface grinding machine driving forces behind this series paves the way to smart manufacturing by meeting the current grinding demands and standards required by the automotive, electric vehicle, mining, aerospace and job shop industries.

Other CHEVALIER - Falcon Machine Tools products

Grinding Machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.