- Machine-tools

- Finishing Machine

- Workpiece grinding machine

- CHEVALIER - Falcon Machine Tools

- Products

- Catalogs

- News & Trends

- Exhibitions

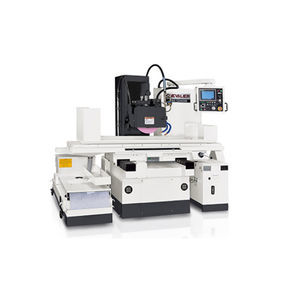

Workpiece grinding machine 618SPmanually-controlledprecision

Add to favorites

Compare this product

Characteristics

- Applications

- workpiece

- Control type

- manually-controlled

- Other characteristics

- precision

- Spindle speed

3,450 rpm

(21,677 rad.min-1)- Power

2 ch

(2 hp)

Description

Table traverses on linear ball bearings & D2 (SKD11) hardened & ground guide ways.

Reinforced ribbed column with hardened & ground guide way system.

Elevating & cross feed lead screws are hardened & ground.

Saddle travels on Turcite-B coated & hand scraped double V guide Ways.

Vertical hand wheel at waist level.

0. 000050" (0.001mm) vertical micro feed.

Permanently lubricated & sealed cartridge-type spindle uses two pairs of class 7 (P4) angular contact ball bearings.

2HP dynamically balanced spindle motor.

Automatic lubrication system.

Meehanite castings.

A mirror surface can be accomplished on these machines accurately and efficiently, due to machine construction features and the specially designed V3 grade spindle motor which provides excellent rigidity and stability.

Double "V" + Turcite-B on Z-Axis

Table Size (W x L): up to 200 x 450mm (8" x 18")

Ballscrew on Crossfeed

Table Surface to Spindle Center:500mm (20")

Parallel Dressing Attachment (Manual).

Micro Crossfeed Device.

Wheel Flange.

Punch Former.

Machine Lamp.

Diamond Dresser.

Crossfeed Ballscrew.

Precision Vise.

Splash Guard.

Universal Wheel Guard For Side Forming.

Rapid Elevation Device.

Elbe Grinding Wheel (For Mirror Surface Grinding).

Balancing Stand.

Balancing Stand (Roller Type).

Chuck Controller (With Variable Holding Power And Auto Demagnetizer).

Permanent Magnetic Chuck.

Inclinable Electromagnetic Chuck.

Inclinable Permanent Magnetic Chuck.

Electromagnetic Chuck.

Combination Coolant & Dust Exhaust Unit (With Magnetic Separator).

Coolant System.

Coolant System With Filter.

Coolant System With Manual Paper Feeding Device (With 1 Roll Of Paper).

Coolant System With Magnetic Separator.

Other CHEVALIER - Falcon Machine Tools products

Grinding Machine

Related Searches

- Grinding machine

- CNC grinding machine

- Precision grinding machine

- Workpiece grinding machine

- Flat grinding machine

- High-precision grinding machine

- Automated grinding machine

- Vertical grinding machine

- Metal sheet grinding machine

- 3-axis grinding machine

- Stationary grinding machine

- Universal grinding machine

- PLC-controlled grinding machine

- High-performance grinding machine

- High-speed grinding machine

- 2-axis grinding machine

- Manually-controlled grinding machine

- Heavy-duty grinding machine

- Hydrostatic grinding machine

- Direct-drive grinding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.