- Industrial machines and equipment

- Furnace and Heat Treatments

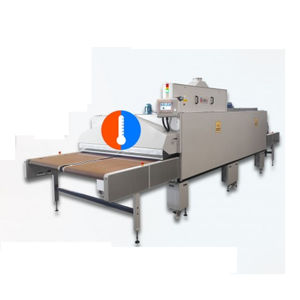

- Hot air dryer

- Chiossi e Cavazzuti srl

Hot air dryer TETRIS 6/8 Mconvectionfor the textile industrywith belt conveyor

Add to favorites

Compare this product

Characteristics

- Technology

- hot air, convection

- Applications

- for the textile industry

- Other characteristics

- with belt conveyor, modular, static

Description

“TETRIS” is an elevated circulation hot air tunnel oven.

It has been designed to dry and polymerize fabrics printed with digital printers using water based

inks. Do not use with inks containing flammable solvents.

Electric heating was chosen because it involves fewer installation and maintenance problems.

The low power consumption does not justify the greater complexity of a gas system, at equal

temperature.

The temperature is adjusted by a precision thermostat and by a long lasting static relay control system. In this manner, the temperature never exceeds the set value thus preventing damage to delicate fabrics.

Advantages:

• In the heat chamber the temperature is uniform and constant on both sides and the center, adjusted by a precise thermostat and by a long lasting static relay control system; in this manner the temperature never exceeds the set value, preventing damage even to the most delicate fabrics. The air exchange is adjusted to discharge steam and promote high volume air circulation. This enhanced airflow convection system is designed on purpose and employs high yeld low noise reverse blades. Outflow nozzles direct the air onto the product perpendicularly and at high speed. Filters on each blower fan achieve an efficient and low maintenance working process.

• The Optional Cooling Hood at the outfeed of the Dryer is an effective cooling system to protect both the operator and delicate products from high temperatures, after the drying process has ended.

Catalogs

No catalogs are available for this product.

See all of Chiossi e Cavazzuti srl‘s catalogsRelated Searches

- Drying system

- Air blast drying system

- Hot air drying system

- Vacuum drying system

- Drying system for the chemical industry

- Drying system with belt conveyor

- Radiation dryer

- Cleaning dewatering system

- Compact drying system

- Stainless steel drying system

- Drying system with temperature control

- Drying system with automatic controls

- Laboratory drying system

- Drying system for the textile industry

- IR drying system

- Vertical dryer

- Curing drying system

- Modular drying system

- Static dryer

- Convection dryer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.