- Industrial machines and equipment

- Furnace and Heat Treatments

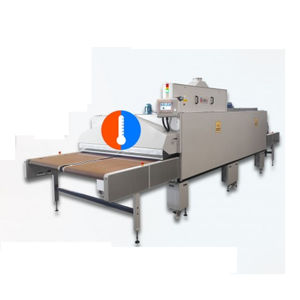

- Hot air dryer

- Chiossi e Cavazzuti srl

Hot air dryer DIDI PROconvectionfor the textile industrycompact

Add to favorites

Compare this product

Characteristics

- Technology

- hot air, convection

- Applications

- for the textile industry

- Other characteristics

- compact, vertical, with temperature control

Description

“DiDO” is the ideal solution thanks to its reduced consumption and compact size.

The hot air guarantees a final effect that cannot be replicated with the other drying solutions: the print keeps the colors vivid and remains flexible, soft and rough to the touch.

The DiDO dryer has been designed to dry water-based, digitally printed inks. DiDo Shop is supplied by 230V monophase.

–

• It works very well with medium-long drying process thanks to the control of the temperature and its efficient air circulation: for this reason it’s perfect for fine fabrics like Lycra, wool, silk and flocked garments.

–

• DiDO is ideal for small factories, laboratories and shops thanks to its reduced dimensions and low consumption.

–

• Hourly production is approximately 60 garments (30 for DiDO Shop) with a permanence of 5-6 minutes per drawer.

–

• Suitable for any type of digital machines, its maximum working temperature is 180°C.

–

• The air is warmed by electrical heating elements and blown in a vertical convection current in order to be uniform everywhere. More so the filtered air keeps the fan and the conduct clean, improving the efficiency and power consumption of the system. The oven is equipped with exhaust extractor and fumes pipe.

–

• Each drawer is independent and equipped with its own timer, indicator light and sound alarm.

–

• Colored touchscreen interface, easy and interactive to use, with important new features like the automatic heating-on and switch-off of the dryer, to minimize the time lost by the operator..

Advantages:

• easy and interactive interface

–

• automatic scheduled start

–

• safe cooling off and sleep mode

–

• precise temperature control

Catalogs

No catalogs are available for this product.

See all of Chiossi e Cavazzuti srl‘s catalogsRelated Searches

- Drying system

- Air blast drying system

- Hot air drying system

- Vacuum drying system

- Drying system for the chemical industry

- Drying system with belt conveyor

- Radiation dryer

- Cleaning dewatering system

- Compact drying system

- Stainless steel drying system

- Drying system with temperature control

- Drying system with automatic controls

- Laboratory drying system

- Drying system for the textile industry

- IR drying system

- Vertical dryer

- Curing drying system

- Modular drying system

- Static dryer

- Convection dryer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.