- Products

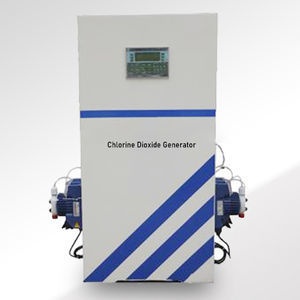

- Liquid chlorine dioxide generator

- Chlory Technology Co.,Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

High-purity chlorine dioxide generator liquidindustrialautomatic

Add to favorites

Compare this product

Characteristics

- Gas characteristics

- high-purity, liquid

- Domain

- industrial

- Other characteristics

- automatic

Description

Chlorine dioxide purity≥95%

Sodium chlorite conversion≥95%

No noise and air leakage pollution

PCL & Skid mounted

PLUG & PLAY

5NaClO2+4HCl →4ClO2+5NaCl+2H2O

Feeding system

Reaction system

Control system

Mixed absorption system

Security system

Residual liquid automatic processing system

Sodium chlorite: (HG/T3250-2001 first grade industrial product, content ≥78%);

Hydrochloric acid: (GB320-2006 industrial first grade product, concentration ≥31%)

2.2g of sodium chlorite, 6.75g of hydrochloric acid (to produce 1g of chlorine dioxide)

Using sodium chlorite and hydrochloric acid as raw materials to prepare liquid high-purity chlorine dioxide disinfectant, the purity of chlorine dioxide is ≥95%, and the conversion rate of sodium chlorite is ≥95%.

The reactor adopts multi-grade industrial titanium-based alloy and fluoroplastic materials, with a long service life.

The material transportation adopts the international famous brand precision metering pump and constant back pressure device, so the raw material measurement is accurate.

The control system adopts intelligent or PLC control system, which is operated by touch keys.

Equipped with RS485 interface, which can realize remote transmission and remote monitoring of equipment operating status signals.

Wastewater disinfection (municipal, hospital): It can kill most of the bacteria in the water, such as E. coli and various types of streptococci.

Water purification and disinfection: Killing algae in water

Fruit and vegetable washing and disinfection.

Other Chlory Technology Co.,Ltd products

Chlorine dioxide Generator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.