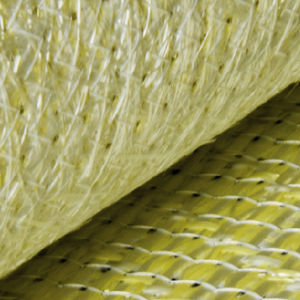

Triaxial technical fabric G-PLY™ FX TL1236 T3glassindustrialcoating

Add to favorites

Compare this product

Characteristics

- Type

- triaxial

- Material

- glass

- Applications

- industrial

- Treatment

- coating

- Domain

- maritime industry

- Other characteristics

- environmentally friendly

Description

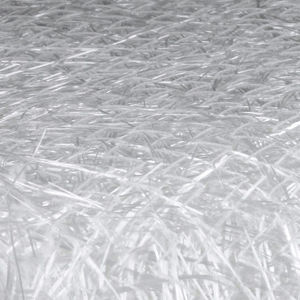

G-PLY™ FX TL1236 T3 is a glass NCF triaxial 0°/+45°/-45° of 1246 gsm. An adhesive coating of 10 g/m² gives it a self-adhesive function.

FX benefits are numerous:

FX is a facilitator of reinforcement positioning and ease lay-up of vertical sections.

Consistent quality:

FX offers weight regularity, the risk of delamination is controlled.

mechanical performance (Interlaminar Shear Strength) is optimal.

Lay-up quality is improved.

Environmental friendly:

FX emits no Volatile Organic Compound (VOC) so it contributes to better working conditions in user facilities.

Time and cost saving:

FX facilitates the lay-up of parts, saving time and reducing the manufacturing costs.

This multiaxial fabric is intended in particular for the Marine industry, primarily for infusion processes but also for HLU processes.

BENEFITS

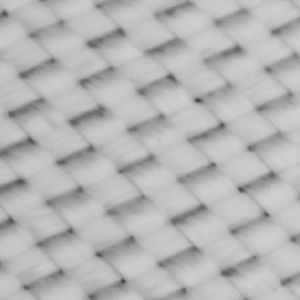

Compared to a woven roving, the specific structure of G-PLY™ with its successive stacking of layers of yarn, without interlacing, provides:

Better mechanical properties.

Optimized resin flow during infusion.

Improved surface appearance: less resin rich areas.

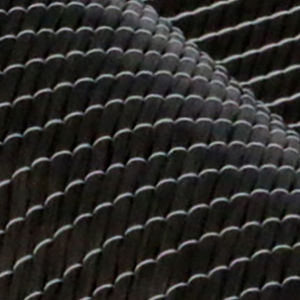

Construction

Total weight: 1256 gsm

Fibres orientation: 0°/+45°/-45° (TL)

0°: 432 gsm - 1200 tex

+45° : 402 gsm - 1200 tex

-45° : 402 gsm - 1200 tex

Coating

Coating - Type: Hot melt

Coating - Weight: 10 gsm

Assembly

Assembly: Stitching Tricot Polyester 3mm

Transformation Process

Infusion

RTM

HLU

Conditioning

Width(s): 127 cm

Roll Length: 60 ml

Catalogs

No catalogs are available for this product.

See all of Chomarat‘s catalogsRelated Searches

- Industrial cloth

- Glass cloth

- Glass fiber

- Reinforcement technical fabric

- Fabric fiber

- Reinforced cloth

- Carbon technical fabric

- Polyester technical fabric

- Coating cloth

- Composite technical fabric

- Glass fiber

- Carbon fiber technical fabric

- Maritime industry technical fabric

- Unidirectional technical fabric

- Fiberglass cloth

- Rubber technical fabric

- Aramid technical fabric

- Cloth for the construction industry

- Non-woven technical fabric

- Biaxial technical fabric

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.