- Metrology - Laboratory

- Metrology and Test Equipment

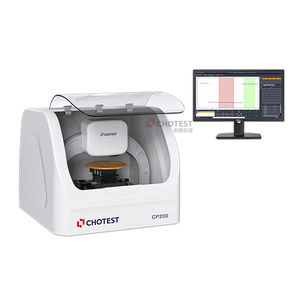

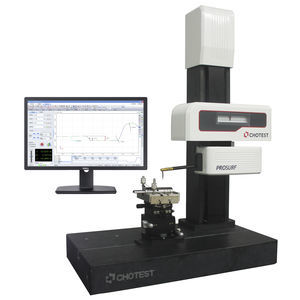

- Direct-contact profilometer

- Chotest Technology Inc.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

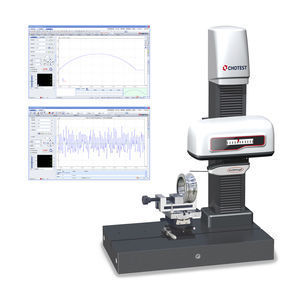

Mechanical profilometer SJ5718-PRdirect-contactfor turned partsindustrial

Add to favorites

Compare this product

Characteristics

- Technology

- mechanical, direct-contact

- Applications

- for turned parts

- Domain

- industrial

- Configuration

- benchtop

- Other characteristics

- automatic, CNC

Description

1. Surface contour evaluation: It can evaluate radius, angle, distance, coordinates, circle, circular cross section, and determine the points, each intersectant point, coordinate axis, straight line, vertical line, circle and circular cross section, and analyze the straightness, roundness of contour;

More functions:

(1)Establish a regression line and a circle

(2)Establish the points, intersectant points, free points, center point, the highest point and the lowest point

(3)Establish the coordinate system

(4)Calculate the radius, distance, angle, coordinates and linear deviation

(5)Compare actual value with nominal value

(6)The measurement program runs automatically

2. CNC Automatic mode is supported; SPC statistics and analysis are supported

3. Support to import CAD file and annotate CAD profile.

4. Support to import PDF profile data.

5. Can export test data to the Word, Excel, AutoCAD(Optional)

6. Output multiple kinds of report format, and support user-defined report, or customize report(optional)

7. Can query and manage the test records according to object type, manufacturer, manufacturing number, inspector, submitted institution, equipment number, inspection date or effective date etc.

8. Can print multiple selected test records or test certificates from database at once time

9. User-friendly software

10. Data backup and restore

Features

1. High precision, high stability, high repeatability: fully meet the measurement requirements of test object.

1)The world's leading high-precision linear encoder system and high-precision inductance measurement system;

VIDEO

Catalogs

No catalogs are available for this product.

See all of Chotest Technology Inc.‘s catalogsRelated Searches

- Test machine

- Chotest measuring instrument

- Chotest measuring system

- Automatic test machine

- Vertical test machine

- Industrial test machine

- Digital measuring device

- Portable measuring device

- Laboratory test machine

- Precision test machine

- Chotest optical measuring system

- Chotest automatic measuring system

- Chotest industrial measuring instrument

- Test machine for the automotive industry

- Chotest high-precision measuring system

- Touch probe head

- Quality control test machine

- Chotest measuring system for industrial applications

- Chotest parts measuring system

- Digital test machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.