1. Once Scanning for both Profile and Roughness parameters such as Ra and Pt

2. Surface roughness: R parameter, P parameter, W parameter, etc.

3. Surface profile evaluation: It can evaluate radius, angle, distance, coordinates, circle, circular cross section, and determine the points, each intersectant point, coordinate axis, straight line, vertical line, circle and circular cross section, and analyze the straightness, roundness of contour

4. Shape error measurement: aspheric shape error measurement, straight line shape error measurement, camber shape error measurement

5. CNC Automatic mode is supported;

6. SPC statistics and analysis are supported

7. Support to import CAD file

8. Can export test data to the Word, Excel, AutoCAD(Optional)

9. Output multiple kinds of report format, and support user-defined report, or customize report(optional)

10. Can search and manage the test records according to object type, manufacturer, manufacturing number, inspector, submitted institution, equipment number, inspection date or effective date etc.

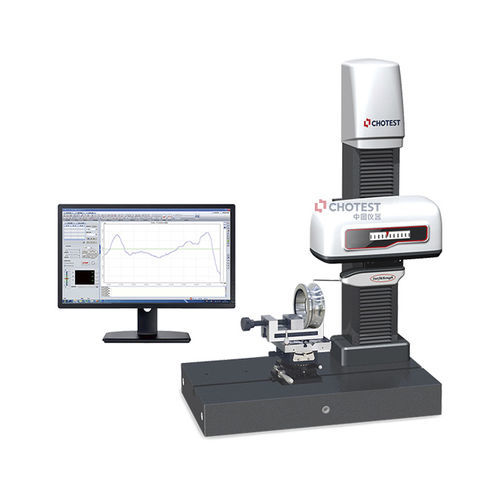

Features

1. Once Scanning for both Profile and Roughness

2. High precision, high stability, high repeatability:

3. Intelligent measurement software

Thanks to friendly software interface, the operator can grasp the basic operation of the machine.

4. Intelligent protection system

Once the measuring probe collides with test object / workholder, or tensile force to measuring probe is too large during scanning process, the machine will stop scanning in order to protect measuring probe and measuring system.

5. Flexible manual control